What Is CTP Machine Working Process

In the modern printing industry, CTP (computer-to-plate) machines, with their advantage of bypassing film and plate making process, have become the core equipment connecting digital files to physical print. However, many practitioners wonder: What are the differences between the workflows of Violet CTP machine and thermal CTP machines?

Common CTP machine working process

Whether it's a violet laser or thermal printer, the core goal of a CTP press is to convert digital prepress files (such as PDFs and Photoshop files) into press-ready printing plates. The overall process follows a five-step process: "File Processing → Plate Preparation → Imaging → Post-Processing → Inspection."

File Processing: Digital Signal Preprocessing

Prepress personnel first use specialized software (such as Adobe Acrobat or Heidelberg Prinect) to perform imposition, trapping, and color calibration on the file to ensure that image and text placement and color reproduction meet printing requirements. The processed file is then converted into a rasterized image file (TIFF/1-Bit TIFF) that can be read by the CTP printer, effectively providing the machine with a blueprint for execution.

Plate Preparation: Loading and Positioning

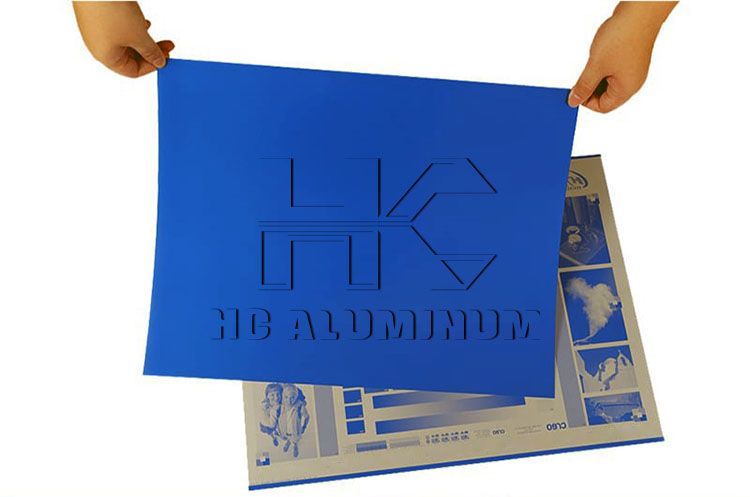

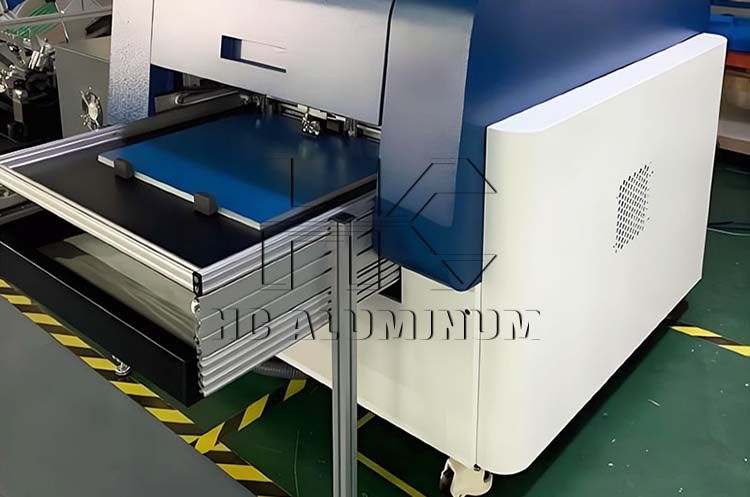

A manual or automated plate loading system feeds a dedicated CTP plate (either violet ctp plate or thermal) into the machine. The plate is secured in place by positioning rollers and a vacuum suction device to prevent shifting during subsequent imaging.

Core Imaging: Light/Heat Development

This is the key difference between the two models: violet laser printers use violet laser light to irradiate the plate for sensitivity, while thermal printers use infrared lasers to heat the plate for development. The specific principles and operational details are completely different, and this is the area we will focus on below.

Post-Processing: Curing and Cleaning

The imaged plate undergoes development, fixing, and drying. The development stage removes the unimaged coating (non-imaged areas), while fixing stabilizes the imaged areas. Finally, a drying device removes moisture from the plate surface to prevent overprinting issues when it is subsequently loaded onto the press.

Quality Inspection: Ensure Usability

The machine's built-in optical inspection system (or manual spot checks) checks the plate for "missing prints, dirty spots, and image offset." Approved plates can be directly sent to the printing press for installation; unqualified plates require re-plating.

Violet CTP machine

A violet laser CTP machine uses a 405nm violet laser as its imaging light source, and its corresponding plate is a photosensitive plate (coated with a photosensitive resin). The workflow has distinct characteristics in the "core imaging" and "post-processing" stages:

Core Imaging: A Violet Laser Triggers a Photosensitive Reaction

After the rasterized file is transferred to the laser system, the violet laser diode selectively illuminates the plate surface based on the image signal. In the illuminated areas (the image area), the photosensitive resin undergoes a chemical polymerization reaction, forming a stable "latent image." Unexposed areas (the non-image area) retain their original coating. This process is similar to the imaging process of a digital camera and is sensitive to ambient light, so the machine interior is typically shielded from light.

Post-processing: Chemical development is required, and the steps are more complex.

After imaging, the plate immediately enters a chemical developing tank. The developer dissolves the unexposed, non-imaged areas, revealing the imaged areas. It then passes through a rinse tank to remove any residual developer, and a fixing tank to solidify the image (to prevent subsequent discoloration). Finally, it is dried. This entire post-processing process relies on chemicals, requiring regular developer replacement and temperature control (usually 20-25°C). This also places high demands on the cleanliness of the operating environment (dust can easily cause smudges in the developed image).

Thermal CTP Machines

Thermal CTP machines use an 830-1064nm infrared laser as their heat source. They use thermal plates (coated with a heat-sensitive resin). The core process relies on replacing light with heat, and their greatest advantage is their environmental adaptability.

Core Imaging: Infrared Laser High-Temperature Development

The infrared laser energy emitted by the laser system focuses on heating rather than exposure. When the laser strikes the plate, the local temperature instantly rises to over 200°C, triggering two reactions (depending on the plate type):

Thermal Ablation Plate: High temperature directly "burns" the coating in the non-image area, leaving the image area intact. No development is required after imaging (i.e., "chemical-free" development).

Thermal Cross-Linking Plate: High temperature cross-links and cures the resin in the image area, leaving the non-image area soluble. Development is required later (but with a milder developer).

Regardless of the type, thermal imaging is independent of ambient light (operating under normal room light). The machine does not require a light-shielding design, making it more flexible to operate.

Post-Processing: Simplified Development or Even Eliminate Processing

If using a thermal ablation plate, development and fixing can be skipped after imaging. Simply clean the ablation residue from the plate surface and then dry it for inspection. This process reduces the number of steps required by 2-3 compared to a violet laser machine, resulting in higher efficiency. While thermally cross-linked plates require development, the developer solution doesn't require strict temperature control and is less susceptible to dust, resulting in lower maintenance costs. Welcome to inquire CTP products from us directly.