What Is Aluminum Litho Plate Market

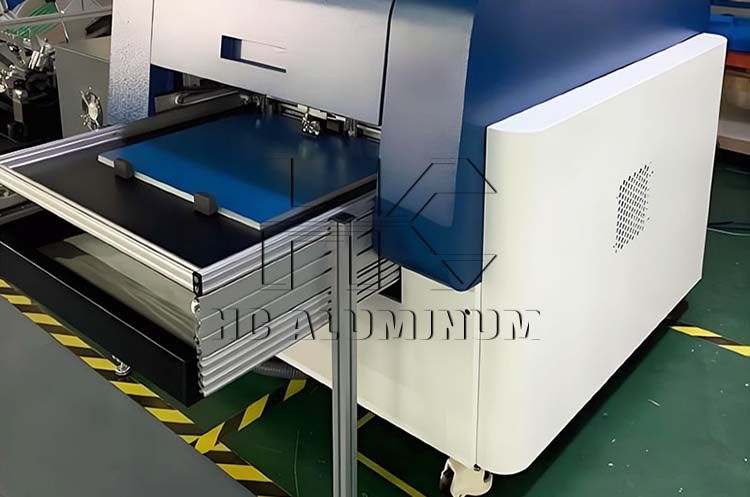

Offset lithography is one of the packaging printing methods. Compared with other packaging printing methods, offset lithography is suitable for economically producing large quantities of high-quality printed products with little maintenance.

Offset printing has the advantages of high printing quality and fast printing speed. In Europe and other regions, offset printing has become a widely used printing method on metal cans because of its hard material and non-absorbent nature.

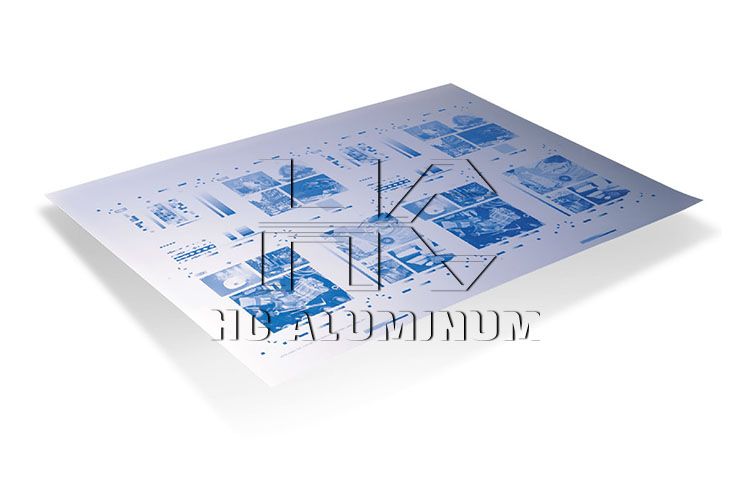

The hydrophilic and oleophilic properties of aluminum lithographic printing plates are relatively good. Because the surface of aluminum has a dense oxide film, it has certain chemical stability, hardness and wear resistance. After process treatment, its hydrophilicity and oleophilicity will be greatly improved. PS plate is currently the main printing plate for pre-printed cartons. Because its platemaking process is simple and fast, the plate installation operation is very convenient. Its printing reproduction effect is good and the printing price is relatively cheap, so it is widely used in printing packaging products such as carton tissue and paper boxes.

According to the data, China's CTP plate exports showed a rapid upward trend. From 2004 to 2019, the export volume showed a stable upward trend. In 2020, China's exports fell, and began to rise in 2021. In 2022, China's CTP plate exports were 185.2446 million square meters.

In recent years, China’s CTP plates have been greatly improved in quality and output, driving its export scale to continue to expand, and has become one of the major exporters of CTP plates in the world. It is expected that green CTP plates will become the mainstream product in the aluminum litho plate market in the future.

Processless CTP Plates are usually a variant of thermal or UV CTP plates. They do not require wetting or chemical treatment to form images, so they are called "waterless" plates. Waterless offset printing removes the uncontrollable water, so there is no ink emulsification phenomenon, and the printed products have uniform ink color and high saturation.

When using waterless offset printing, generally 5 sheets of paper are consumed for formal printing, with low paper consumption and high production efficiency. As an advanced printing technology, waterless offset printing has the potential to replace traditional water-based offset printing.

Haomei Aluminum has rich types of CTP offset printing plates. Welcome to leave message below to inquire what you need.

What Are Thermal CTP Plate Types and Their Applicable Characteristics

What Are The Benefits of Positive PS Plate for Offset Printing