Which Printing Plates Choose Aluminum Plates As Raw Materials

In the printing industry, aluminum plates are an important raw material and are widely used in the production of various printing plates. So, which printing plates will choose aluminum plates as raw materials? What are the considerations behind this?

Types of printing plates

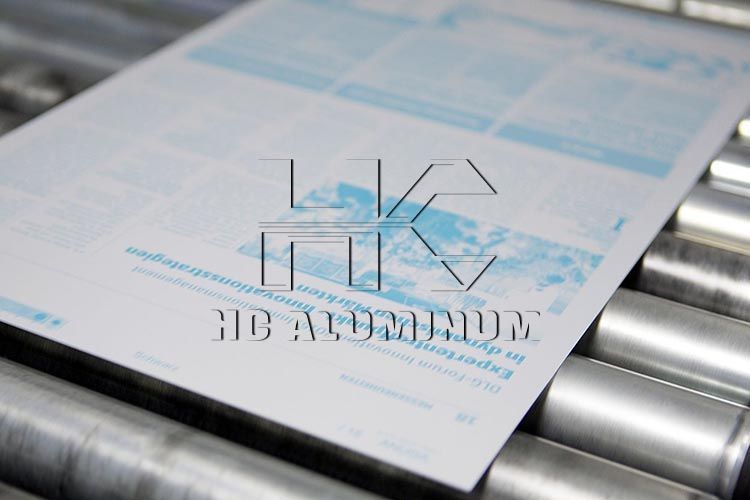

PS plate (pre-coated photosensitive plate): PS plate is a widely used printing plate in the current printing industry. It is made by coating a photosensitive liquid synthesized from diazonium salt and phenolic resin on an aluminum plate that has been electrolyzed and anodized.

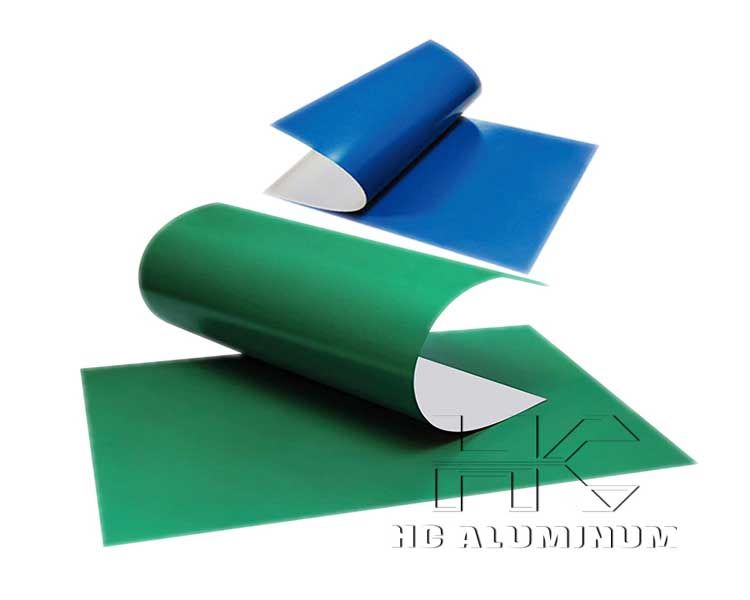

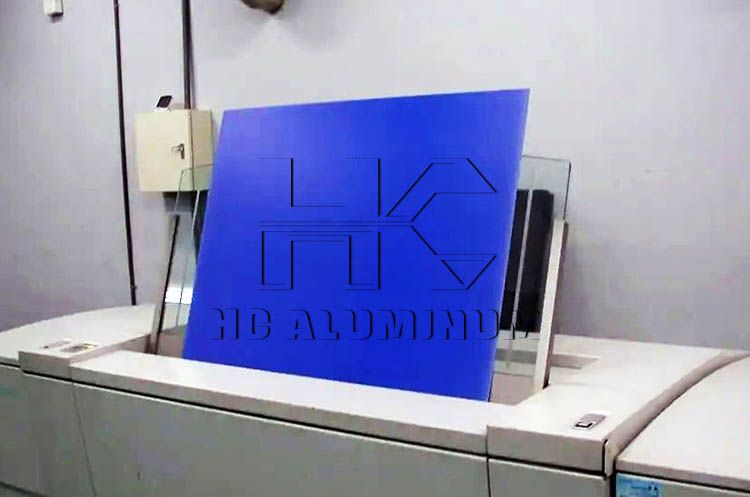

CTP plate (computer-to-plate plate): CTP plate also uses aluminum plate as the base material. Through hot and cold rolling processes, aluminum alloy blanks are rolled into thin plates of a certain thickness. Then the surface of the plate is treated with a specific process and coated with a layer of photosensitive resin. After drying, the CTP plate is made.

It realizes the direct platemaking process from computer to printing plate. In modern printing, especially in commercial printing, packaging printing and other fields with extremely high requirements for printing quality and efficiency, CTP plate occupies an important position.

CTCP plate: As an important branch of CTP plate, the customized uv ctcp plate also uses aluminum plate as substrate. It uses UV light source for exposure, and has unique design in aluminum plate surface treatment and photosensitive coating formula, which can better meet the needs of UV printing process.

It is widely used in packaging printing, commercial printing and other fields with high requirements for printing effect and environmental protection. With the stable performance of aluminum plate substrate and special photosensitive coating, it can achieve high-precision and high-endurance printing effect.

Why aluminum sheets are favored

Good hydrophilicity and oleophilicity: The hydrophilicity and oleophilicity of metal aluminum are at a moderate level, which makes its wetting properties easy to change. During the printing process, the printing plate needs to be oleophilic in the image part and hydrophilic in the blank part. This characteristic of the aluminum plate can just meet this demand. Through the subsequent surface treatment process, the printing plate surface can accurately form the image area and blank area that meet the printing requirements.

Excellent physical properties

Low density and high strength: The density of the aluminum plate is relatively small, which makes the printing plate lighter while ensuring strength, and easy to carry and install. At the same time, it has high strength and can withstand mechanical forces such as pressure and friction during the printing process. It is not easy to deform, which ensures the durability of the printing plate and the stability of the printing process.

Moderate wear resistance: During the printing process, the printing plate is constantly in contact with the rubber blanket, paper, etc. The moderate wear resistance of the aluminum plate enables it to maintain the integrity of the surface during multiple printings and will not wear out too quickly, thereby ensuring the consistency of printing and the long service life of the printing plate, reducing the printing cost.

High chemical stability: Aluminum easily forms a dense aluminum oxide protective film in the air, which can prevent the aluminum plate from further oxidation and corrosion, ensuring the stability of the printing plate in different environments.

Good surface treatment: The surface of aluminum plate can be treated in many ways, such as anodizing, electrolytic corrosion, etc. Through anodizing treatment, a hard and porous oxide film can be formed on the surface of the aluminum plate. This oxide film not only enhances the wear resistance and corrosion resistance of the aluminum plate, but also provides a better adhesion basis for subsequent processes such as coating photosensitive resin, thereby improving the quality and performance of the printing plate. Through the method of electrolytic corrosion, a large number of dense concave and convex micro-grits can be formed on the smooth surface of the aluminum plate. These grains are of great significance for improving the resolution, dot finish and ink transfer performance of the printing plate.

Resource and cost advantages: Aluminum is a metal element with extremely rich reserves in the earth's crust, and its resources are abundant, which makes the supply of raw materials for aluminum plates stable and sufficient. Compared with some rare metals, the price of aluminum plates is relatively reasonable, which can effectively control the production cost of printing plates.

At the same time, aluminum has good recyclability and easy regeneration. Abandoned aluminum printing plates can be recycled and reused, which not only reduces the impact on the environment, but also reduces production costs to a certain extent, which is in line with the concept of modern green environmental protection and sustainable development. HC printing has its own aluminium printing plates factory. Welcome to inquire what you need from us directly.