Printing Plates For Corrugated Boxes

In the packaging industry, corrugated boxes have become the preferred packaging material for commodity transportation and storage due to their good cushioning performance, recyclability and cost advantages. As a key link in giving corrugated boxes beautiful appearance and information transmission function, the choice of printing plate is crucial.

Commonly used printing plate types for corrugated boxes

Flexographic printing plate

Flexographic printing is one of the mainstream methods of corrugated box printing. Flexographic printing plates are usually made of rubber or photosensitive resin materials. It has the characteristics of good elasticity and low printing pressure. It can adapt to the uneven surface of corrugated boxes. It performs well in solid printing and line printing. The platemaking process is relatively simple and the cost is low. It is suitable for medium and short-run corrugated box printing.

Offset printing plate

Offset printing plate is also used in corrugated box printing. It realizes image transfer through the principle of water-ink balance. The printed images are of high precision and good color reproduction. It can present rich and delicate pictures. It is suitable for corrugated box printing with high printing quality requirements and rich image layers. However, offset printing has high requirements for the flatness of corrugated board and high printing pressure, which may have a certain impact on the compressive strength of corrugated box.

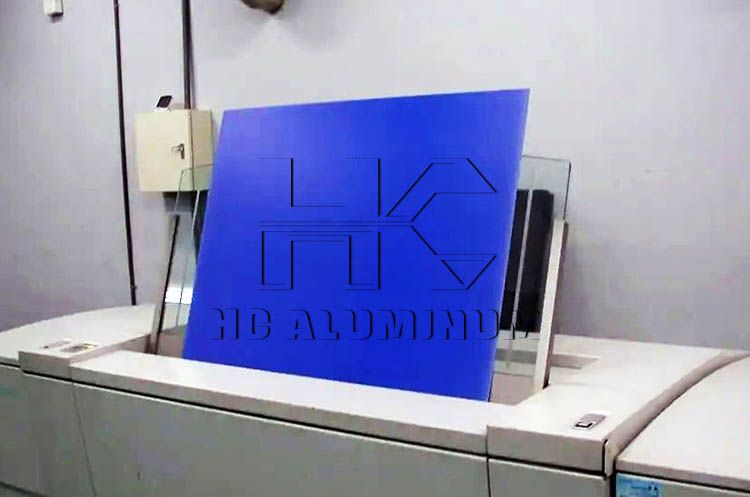

Characteristics of CTCP plate

CTCP plate is developed on the basis of traditional PS plate and combined with computer direct platemaking technology. It uses thermal technology or purple laser technology to directly expose digital images on traditional positive or negative PS plates, omitting the film output link.

CTCP plate has the following advantages

High plate-making efficiency: plate-making directly from computer files reduces the intermediate links such as film production and plate imposition, greatly shortens the plate-making time, and improves production efficiency.

Stable printing quality: avoids problems such as dot deformation and scratches that may occur during the production and transfer of films, can accurately restore images, and ensure the stability and consistency of printing quality.

Cost advantage: reduces the use of film and reduces material costs; at the same time, the improvement of plate-making efficiency also indirectly reduces labor and time costs.

Analysis of the applicability of CTCP plates in corrugated box printing

Quality assurance: The UV CTP can accurately restore the dots and details of the image, and can effectively improve the printing quality for some corrugated paperboard printing that needs to present exquisite patterns and complex text information. For example, in the printing of high-end gift packaging corrugated paperboard, CTCP board can make the brand logo and product pictures on the packaging clearer and more realistic, enhancing the attractiveness of the product.

Efficiency improvement: Its fast plate making speed has great advantages for corrugated paperboard printing projects with urgent orders or short delivery times. During e-commerce promotions and other activities, merchants' demand for corrugated paperboards has increased dramatically. CTCP plates can help packaging companies quickly make plates and produce to meet market demand.