What Will Process Free CTP Plate Bring for You

With the development of printing technology, various CTP technology systems are developing a process free printing plate that does not require chemical development. What we offer is process-less thermal CTP plate.

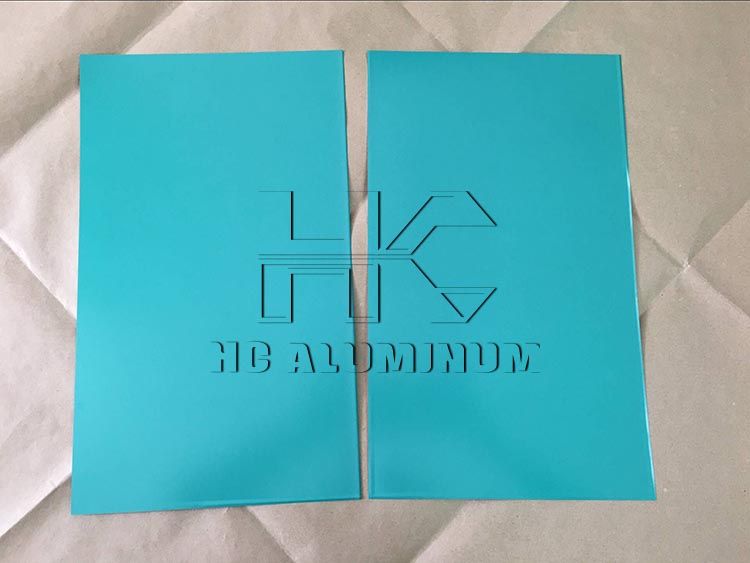

It can be used on any CTP thermal platemaking machine (830nm). The plate base is a standard electrochemically frosted and anodized aluminum sheet with a single coating. The coating liquid contains ink-loving hot-melt particles. Because the particles are small, they are sufficient to receive high-intensity laser beams. This is the using effect of our process free printing plate.

Features of processless CTP plate

1. Compared with traditional CTP plates, unprocessed plates eliminate the steps of development, fixing, cleaning, gluing, drying, etc., shorten the platemaking cycle, reduce the amount of energy consumed during exposure, reduce the overall platemaking cost, improve production efficiency, and simplify the production process.

2. Since process less plates do not require chemical development and washing, the platemaking process of unprocessed plates will not produce chemical waste liquids, waste gases, and waste residues that damage the environment, reducing pollution to the environment and is beneficial to printing operators.

3. Changes in plate washing conditions, laser energy, and the concentration of the washing solution will affect the stability of CTP plates, and the treatment-free plates that do not require washing can have higher quality stability.

4. Process-free plates do not require chemical development equipment, saving factory space, which is a major advantage for small companies, but process-free plates are more expensive than conventional CTP plates. Welcome to choose the right printing plates from us.