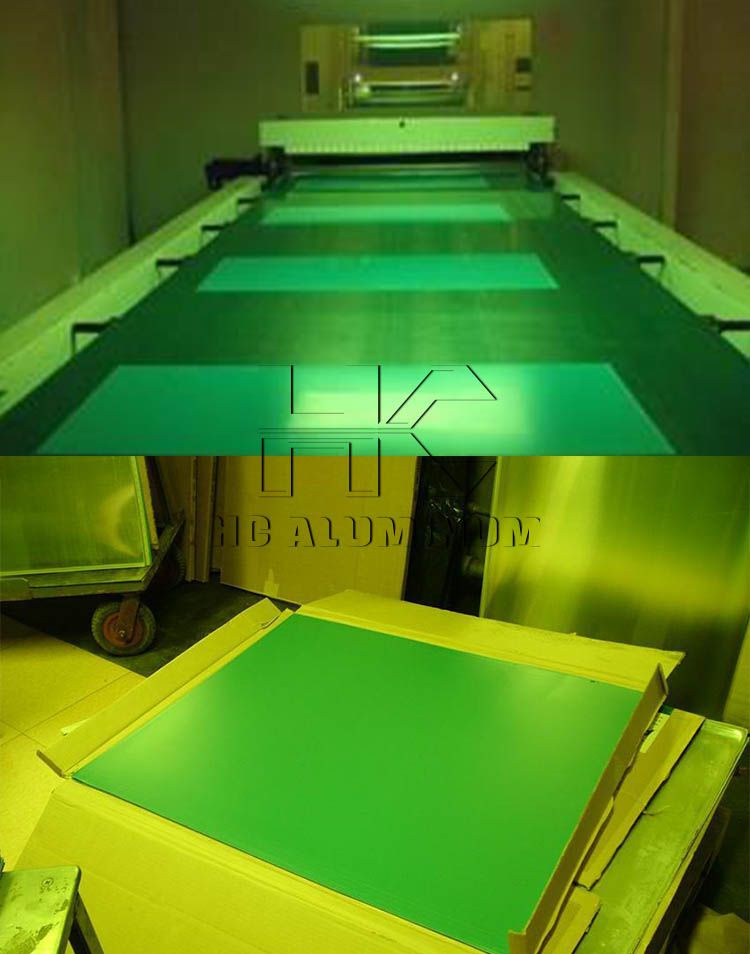

PS PlateWith mature PS manufacturing and testing technologies, HC’s PS plate features fine grain, high resolution and high print durability, up to 300,000 sheets. Cheap price, inquire now!

|

|

What is PS plate meaning

PS plate(Presensitized Plate) consists of an aluminum sheet and a layer of coating, i.e., a photosensitive layer. The photosensitive layer is a layer formed by coating the photosensitive liquid on the substrate. The printing industry has long used PS plates in large quantities.

As long as the black draft is done, exposed and developed, it can be printed on the machine, with large printing volume and good quality. Now with computerization, even black draft editing, film production, printing... are automated. There are two types of PS plates: negative and positive. Now positive PS plate is more commonly used. We also have thermal ctp for you.

Positive PS plate specification

Name | Positive PS Plate |

Usage | Offset Printing, Digital Printing |

Spectral Sensitivity | 320-450nm |

Resolution | 2-99% |

Thickness | 0.15-0.30mm |

Colour | Green |

Specification | 0.15mm100PCS/box;0.30mm50PCS/box. |

Material | Aluminum |

LongImpression | 60000-100000impressions. |

Sizes | Customized sizes |

Developer Temperature | 23+/-2Degree |

Laser Energy Required | 80-180mj/Cm2 |

Transport Package | Export Standard Seaworthy Package |