Process-less CTPThe use of processless printing plates eliminates the steps of developing,fixing,cleaning,gluing,drying,etc.,saving time and equipment cost.

|

|

What is process free ctp

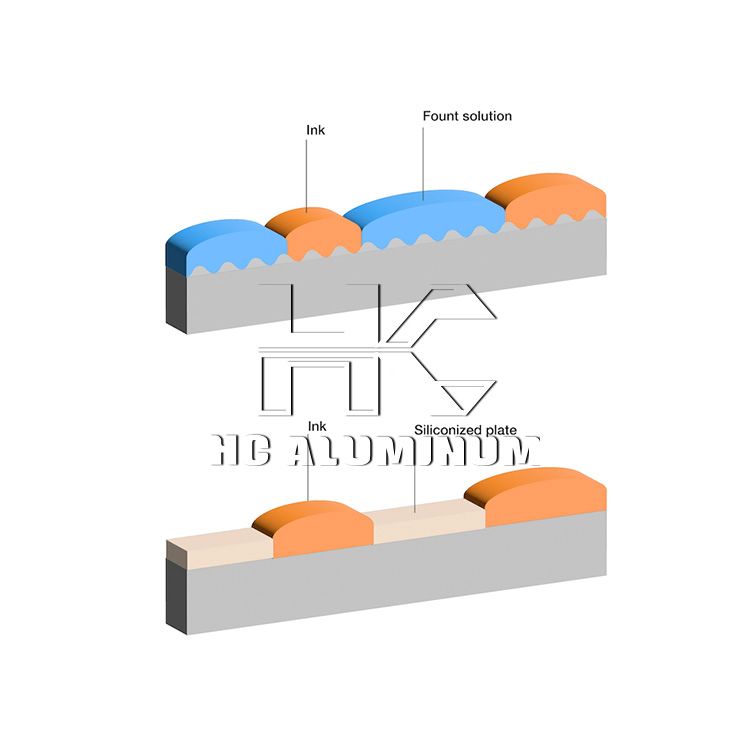

After the process free ctp plate is exposed and imaged on the direct plate-making equipment, it can be printed on the machine without any subsequent processing steps. Compared with traditional CTP plates, it eliminates the steps of developing, fixing, cleaning, gluing, drying, etc., has higher quality stability, improves work efficiency, reduces environmental pollution and equipment cost investment. The dot reproduction reaches 1-99% at 200 lines.

Processless printing plate specification

Product type | Process-less thermal CTP plate |

Usage | High quality commercial and newspaper printing |

Style | Negative |

Resolution | 2-99 % |

Thickness | 0.15-0.30 mm |

Colour | Grey |

Specification | 0.15mm100PCS/box; 0.30mm50PCS |

Material | Aluminum |

Type | CTP Plate |

Long Impression | 60,000-100,000 impressions |

Developer Temperature | 23+/-2Degree |

Laser Energy Required | 80-180mj/Cm2 |

Transport Package | Export Standard, Seaworthy Package |