What Are Features of Waterless Printing Plates

Waterless printing plates, as the name suggests, remove the involvement of water compared to common lithographic water offset printing, and does not require aqueous solution to moisten the plate. It uses an ink-repellent silicone rubber layer (silicone resin) as the non-image part of the printing plate, and uses special ink to complete the printing.

Its birth aims to solve the problems such as water and ink balance in the offset printing process, as well as the loss of gloss, paper deformation, and slow drying of printed products caused by ink emulsification.

The difference between waterless printing system and traditional printing system

The overall architecture of waterless printing is similar to that of traditional offset printing system, but there are significant differences in the requirements of plate materials, inks and printing environment.

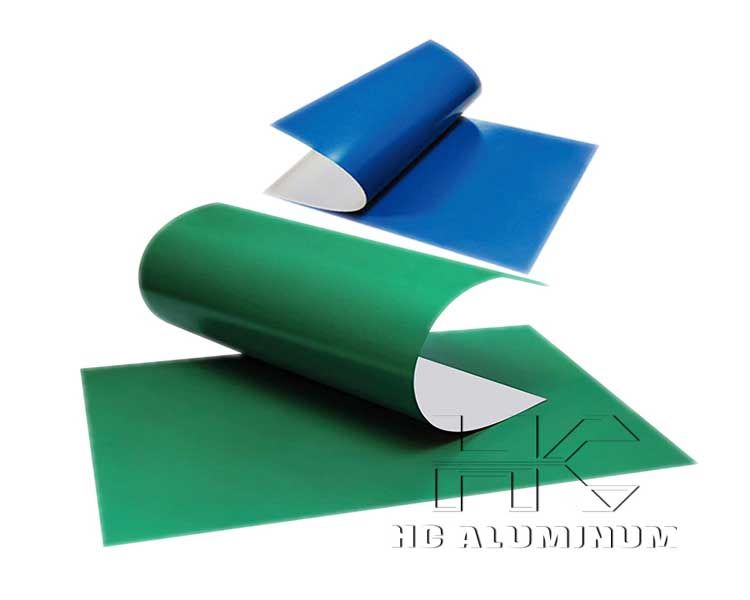

Different plate structure

The traditional water-based offset printing plate is a flat-convex structure, while the waterless offset printing plate is a flat-concave structure. The bottom layer is an aluminum base plate, which is coated with a layer of photosensitive polymer material as an intermediate layer, and the top layer is a 2-micron thick silicone rubber layer.

Special requirements for ink

Waterless printing requires the use of special inks specially adapted to match the process characteristics of waterless printing to ensure the smooth progress of the printing process and printing quality.

Strict requirements for temperature

In the waterless printing system, the viscosity of the ink is closely related to the temperature of the ink, and the working temperature of the ink is limited to a very narrow range of 3-4℃. Once it is higher or lower than this temperature range, the ink will become unstable, which will seriously affect the printing quality. Therefore, in order to achieve precise control of the printing effect, the printing factory usually needs to be equipped with air conditioning for temperature control.

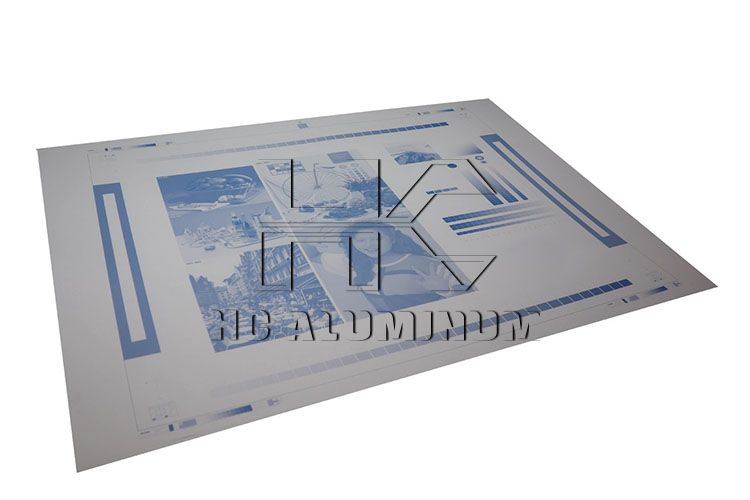

Structure and principle of waterless offset printing plate

Waterless offset printing plate (including waterless offset CTP plate) is generally composed of aluminum plate base, photosensitive layer and silicone layer.

Aluminum plate base

The aluminum plate base mainly supports the printing plate and provides a stable foundation for the entire printing plate structure.

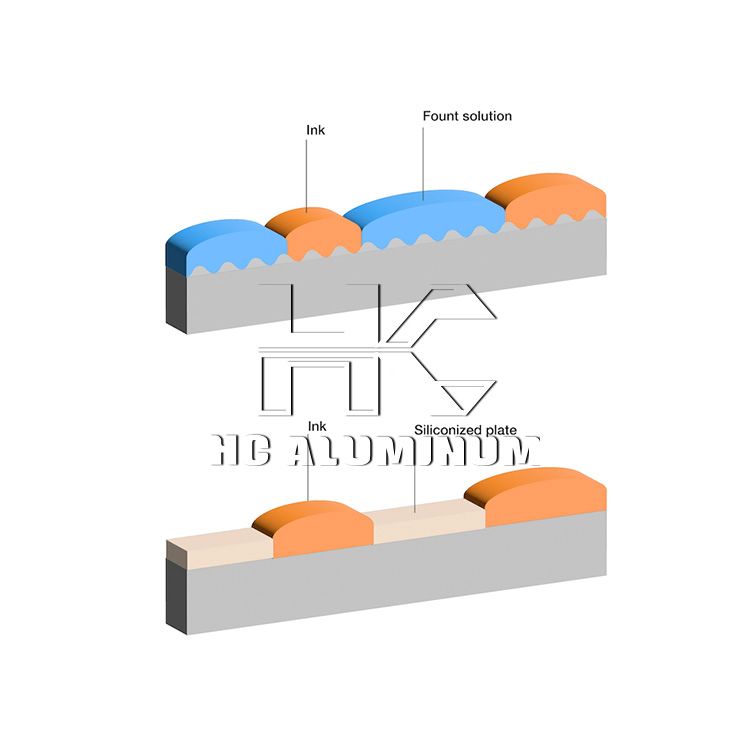

Photosensitive layer

After the offset printing plate is exposed to light, the photosensitive layer will undergo a chemical reaction, resulting in a decrease in its adhesion to the silicone layer. After the development process, the weak adhesion part of the silicone layer will be washed away, thereby exposing the photosensitive layer. In subsequent printing, the exposed photosensitive layer can absorb ink to form the image part.

Silicone layer

The silicone layer plays a similar function to the fountain solution in waterless offset printing, that is, it repels ink during the printing process to form the non-image part.

Waterless offset printing plates use the low surface energy characteristics of silicone to repel ink. When the ink layer contacts the silicone layer, the solvent in the ink will quickly diffuse and penetrate into the silicone layer, causing the surface of the silicone layer to swell and form a solvent layer between the two.

During the continuous printing process, the ink layer will separate from the surface of the silicone layer, so the surface of the silicone layer will not directly absorb the ink.