What Is Process Free CTP Plate Market

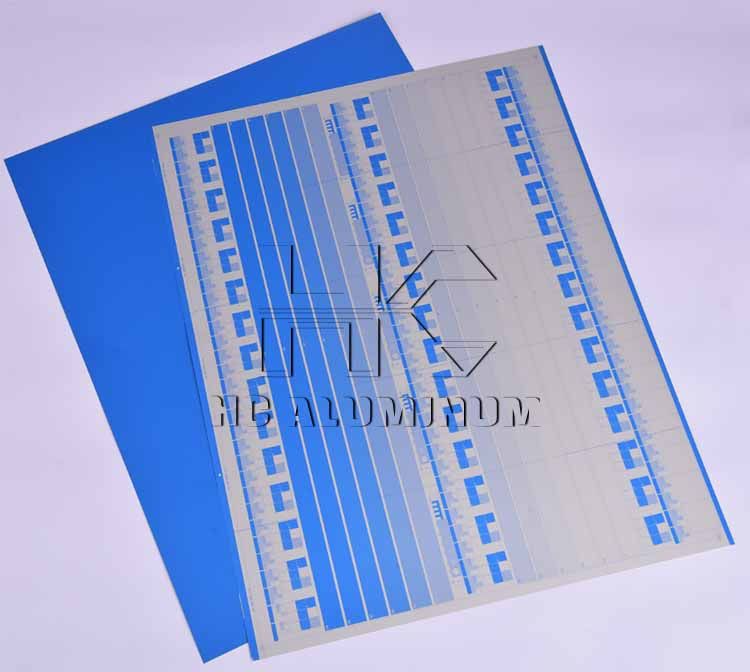

The process free CTP plates are also known as processless plates. The product goes directly from the imager to the press while avoiding additional processing steps. Thus, it helps in eliminating processing steps, simplifying the platemaking process, increasing productivity, reducing waste, and cutting costs in the pressroom and prepress.

Moreover, process-free CTP plates help in providing non-ablative, negative offset, and high chemical resistance properties. These factors make process-free CTP plates a sustainable option and have significantly increased its demand in the commercial printing and packaging industries.

The growing demand for printing for various purposes will increase the consumption of process-free CTP plates. The widespread adoption of newspaper printing, the growing demand for printed books and papers, and the increase in the consumption of product packaging printing due to the provision of various information to consumers have led to a surge in the demand for printing.

The cost-effectiveness and chemical resistance of process-free CTP plates contribute to the increase in demand for process-free CTP plates. Hence, the rapid growth of the printing industry will help drive the growth of the process-free CTP plates market during the forecast period.

Although the price of processless printing plates is higher than that of conventional CTP plates, the former can save 35% of the total cost in terms of the overall platemaking cost, so the high price of each treatment-free plate is understandable.

Features of processless plates

1. Compared with traditional CTP printing plates, the processless printing plates eliminate the steps of development, fixing, cleaning, gluing, drying, etc., shorten the platemaking cycle, reduce the amount of energy consumed during exposure, reduce the overall platemaking cost, improve production efficiency, and simplify the production process.

2. Since the treatment-free plate does not require chemical development and washing, the plate-making process of the treatment-free plate will not produce chemical waste liquid, waste gas and waste residue that damage the environment, which reduces pollution to the environment and is beneficial to printing operators.

3. Changes in plate washing conditions, laser energy, and the concentration of washing liquid will all affect the stability of CTP plates, while non-processing plates that do not require washing can have higher quality stability.

4. Non-processing plates do not require chemical development equipment, which saves plant space and is very beneficial to small companies.

How to correctly choose a process free CTP plate

Choosing a suitable treatment-free CTP plate is crucial for printing companies. When choosing a treatment-free CTP plate, you must first understand the principle of the treatment-free CTP plate and know its types, and then choose the appropriate type of treatment-free CTP plate according to your own production and process flow. In addition, printing companies also need to measure the cost increase or decrease that can be brought about by trying out processless CTP plates.