What Are Negative and Positive Printing Plates

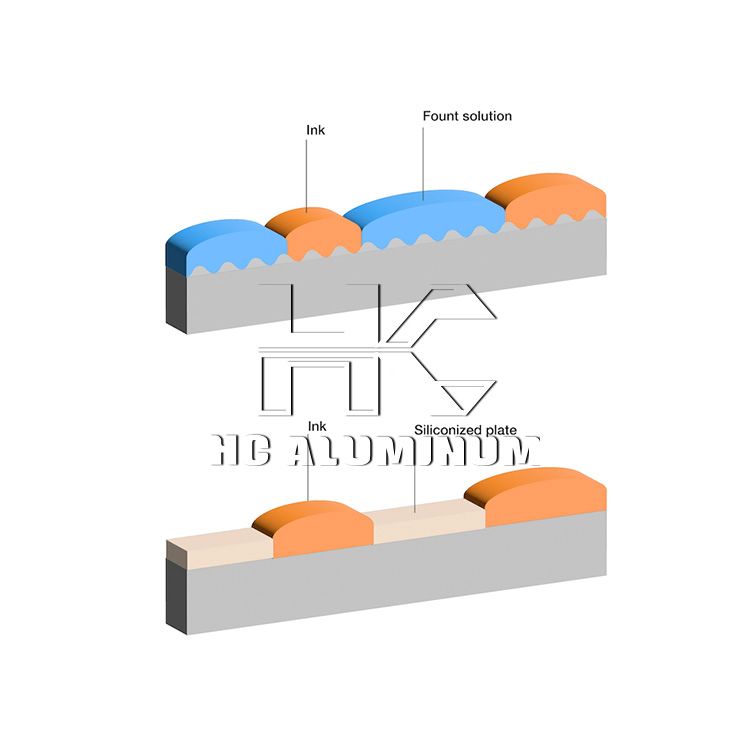

Printing plates are the key link between the original design and the finished printed product. Positive and negative printing plates are the basic types of printing plates. The essential difference between positive and negative printing plates lies in the correspondence between the "image area" and "blank area" on the plate and the design original (such as a PDF file or film).

1. Positive printing plates

The core feature of a positive printing plate: the image area on the plate is identical to the image area of the original.

After exposure and development, the printable area on the plate remains, representing the text, images, and other content in the original. Blank areas in the original are removed after development, becoming unprintable areas. Currently, positive printing plates are more widely used.

2. Negative Printing Plates

The core characteristic of negative printing plates is that the image and text areas on the plate are completely opposite to those on the original.

Text, patterns, and other content in the original become blank areas on the plate; blank areas in the original become printable areas. Negative printing plates are primarily used in the pre-production stages of some flexographic and gravure printing processes. They are rarely used directly in lithographic printing (such as book and poster printing) because they require additional reverse processing of the original, making the process more complex.

PS plate

PS plates (pre-sensitized plates) are commonly used in lithographic printing and are categorized as positive and negative. Currently, the positive PS plate is far more widely used than negative PS plates for the following reasons:

Strong process adaptability: Mainstream printing processes (such as CTP) output positive-type files by default.

Lower operating requirements: Positive PS plates have highly stable exposure and development parameters and are less sensitive to ambient temperature and humidity.

Cost and Supply Chain Advantages: Positive PS sheets have high market demand, mature production technology, and are priced lower than negative PS sheets. Suppliers maintain ample inventory, resulting in a stable supply chain and less risk of stockouts.

CTP plate

CTP plates (computer-to-plate) are an alternative to traditional PS plates. CTP thermal plates are currently the mainstream product in the CTP market, and the vast majority are positive-working. The working principle of thermal CTP plates: A CTP platesetter (typically with a laser wavelength of 830nm) illuminates the plate. The image areas exposed to the laser undergo a chemical change (such as hardening the resin). After development, the hardened image areas are retained, while the unexposed blank areas are removed. This process ensures that the image areas on the plate are consistent with the original image areas, which is the core characteristic of a positive-working plate.

Furthermore, thermal CTP plates do not require light protection during operation (unlike violet CTP plates, which do require light protection), offering high flexibility in workshop operation, high resolution, and a long run (capable of printing runs of hundreds of thousands to millions of copies). They are currently widely used in the book, packaging, and commercial printing industries.

What Is CTP Machine Working Process

Which Kind of Printing Plates Are Suitable for Commercial Printing