Digital Thermal Plate for Offset Printing

In today's rapidly developing printing industry, offset printing, as a widely used printing process, is constantly striving for higher efficiency, better quality, and lower costs. The emergence of digital thermal plates has undoubtedly injected strong momentum into the upgrading of offset printing technology. With its unique technological advantages, it has gradually replaced traditional printing plates and become the new favorite in the offset printing field.

The traditional offset printing plate production process is complex, requiring multiple steps, including film output, plate exposure, and development. This process is not only time-consuming but also susceptible to environmental factors (such as temperature and humidity), resulting in unstable plate quality. Furthermore, the production of traditional plates produces wastewater, which pollutes the environment and is inconsistent with the current development of green printing.

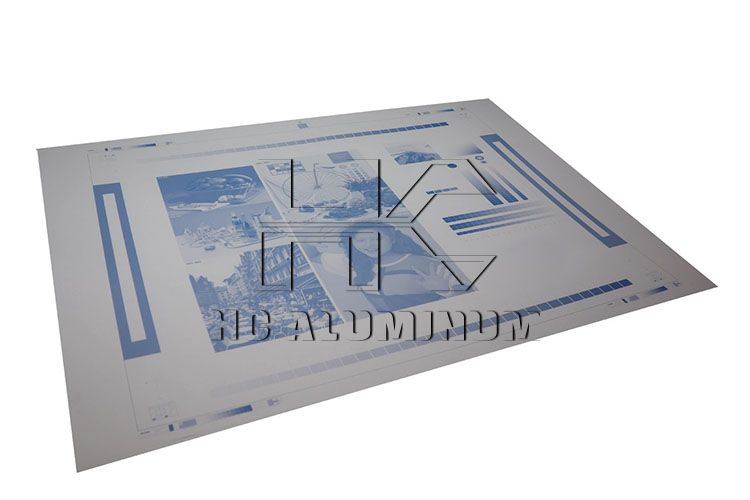

Digital thermal plates perfectly address these pain points. Using thermal imaging technology, they eliminate the need for film and transmit image information directly from a computer to a thermal platesetter. Laser scanning then causes the heat-sensitive coating on the plate surface to undergo a physical or chemical change, creating the printable image.

This process not only eliminates multiple intermediate steps and significantly reduces platemaking time from hours to minutes, significantly improving production efficiency, but also avoids waste discharge and is more environmentally friendly. Furthermore, digital thermal plates offer high imaging precision, enabling clear reproduction of fine image details, meeting the demands of high-quality printing. Whether complex patterns or fine text, they can be accurately rendered.

Advantages

High Resolution: Digital thermal CTP plates typically achieve imaging resolutions of 2400 dpi or higher, clearly rendering fine dots and tiny text. This meets the demands of high-quality printing, such as for brochures, magazines, and packaging, enhancing detail and vibrant colors.

Wide Color Gamut: The digital thermal plate's thermal coating exhibits excellent ink absorption and transfer properties, enabling accurate reproduction of a wide range of colors. This makes it an excellent choice for color printing, meeting the personalized color needs of diverse clients. Whether it's vibrant advertising posters or softer book illustrations, precise printing is guaranteed.

Excellent Print Run: The digital thermal plate's surface coating undergoes a special treatment for high wear and corrosion resistance, allowing it to withstand significant pressure and friction during the printing process. Its print run typically exceeds 100,000 impressions, with some high-quality plates exceeding 500,000. This is crucial for high-volume printing, reducing plate changes, improving production efficiency, and lowering costs.

Stable Print Quality: The digital thermal plate's imaging process is stable and unaffected by environmental factors, ensuring consistent quality from plate to plate. Furthermore, the ink and water affinity of both the image and blank areas of the plate remain stable during the printing process, preventing plate dropouts or smearing, ensuring consistent and reliable print quality.

Applications

Commercial Printing: In the commercial printing sector, digital offset plates are widely used in the production of printed materials such as brochures, magazines, posters, and flyers. Their high resolution and wide color gamut meet the high-quality, color reproduction requirements of commercial printing, helping companies better showcase their products and brand image and enhance their promotional effectiveness.

Packaging Printing: Packaging printing places high demands on printing plates, requiring not only clear images and text but also excellent print durability and stability to accommodate mass production. Digital thermal plates, due to their superior technical characteristics, are widely used in packaging printing applications such as food, pharmaceutical, and cosmetics. They can accurately print logos, designs, and text on packaging while ensuring consistent quality, meeting the stringent requirements of packaging printing.

Book and Periodical Printing: As demand for book and periodical printing quality continues to rise, digital thermal plates are becoming an ideal choice for this sector. They can clearly print text and images, ensuring a pleasant reading experience. Their excellent print durability meets the needs of mass printing and reduces production costs. Whether it's textbooks, novels, or reference books, digital thermal plates are highly effective.