What Are Thermal CTP Plate Types and Their Applicable Characteristics

As we all know, the CTP process can bring many benefits to printing: excellent imaging quality, near-perfect calibration, and fast production turnover. However, its advantages are not only due to the imaging equipment, but also rely on the quality and performance of CTP plates.

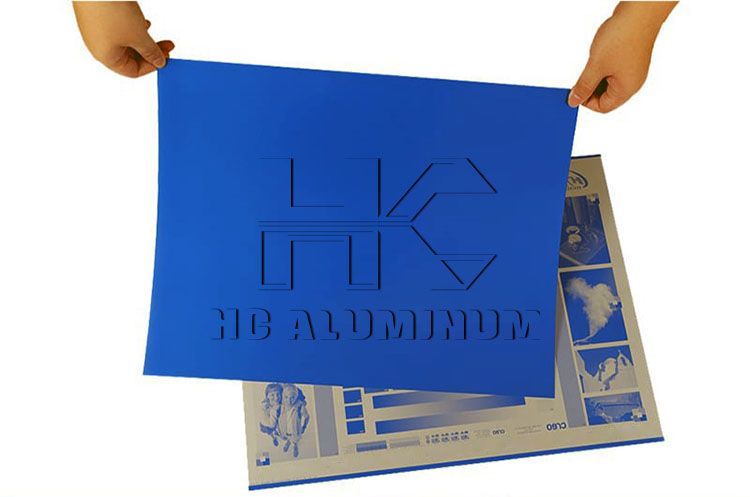

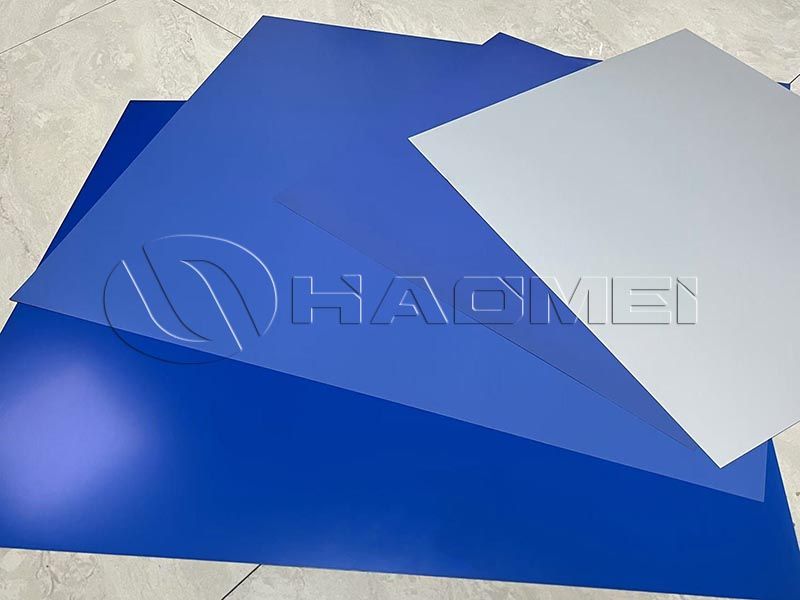

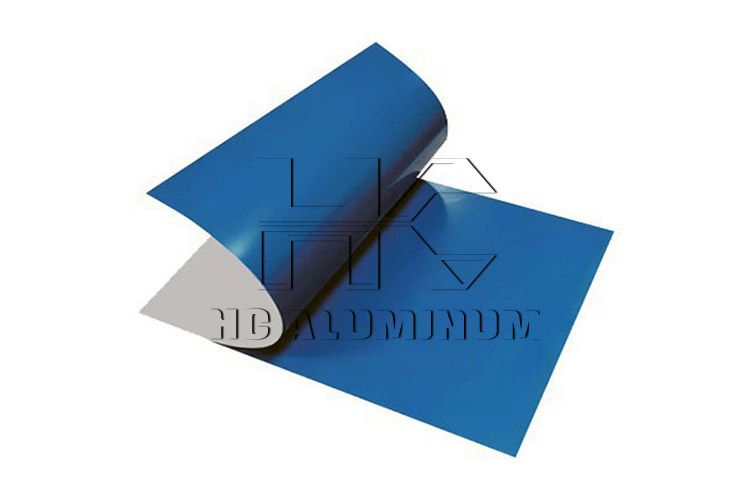

Thermal CTP plate is the preferred printing plate choice for printers to adopt CTP systems. Thermal plates will bring users precise quality and stable high quality. Thermal CTP plates account for about 60-70% of the total production, UV-CTP plates account for about 25%, and photosensitive and other CTP plates account for less than 10%.

Thermal CTP plates are the most widely used CTP plates at present. It uses thermal imaging technology to make plates and is very sensitive to the heat energy of the laser, so it can achieve high-precision image and text transfer. Thermal CTP plates are suitable for high-quality commercial printing and publication printing, such as high-end magazines, albums, brochures, etc.

Double layer ctp plate has two layer coatings: one layer is photosensitive glue, and the other layer is a particularly durable film. This coating method can greatly increase the printability. It is suitable for both packaging printing and commercial printing, such as posters, images, product manuals, toy packaging, corrugated boxes, and is compatible with most developers on the market.

In recent years, as the concept of green printing continues to gain popularity, various CTP plates with more environmentally friendly characteristics, such as chemical-free plates and waterless offset plates, have been continuously introduced to the market and successfully applied by some printing companies, further improving the environmental attributes of CTP plates.

The graphic part of the negative type waterless plate is slightly concave, and the ink is not easy to spread after inking. The silicone rubber layer in the blank part has a repelling effect on the ink. Therefore, no wetting liquid is needed during printing, thus avoiding many faults caused by the wetting liquid.

The ink used in waterless offset plates has lower viscosity and adhesion than water-based offset printing ink. The main components are high-viscosity modified phenolic resin and high-boiling non-aromatic solvents, which are easily decomposed when heated. Therefore, the ambient temperature should be kept appropriate during printing.

What Are Advantages & Disadvantages of Using PS Plates for Printing