Aluminum Litho Plate: CTP Plate and Its Developer

PS plate and CTP Plate have the advantages of high printing quality, strong printing durability, good environmental protection, reasonable cost, high resolution, fast speed and strong reproducibility.

Compared with other bases, aluminum plates have occupied a dominant position in printing plate substrates due to their light weight, high strength, moderate wear resistance, good hydrophilicity, high stability and easy surface treatment.

In the publishing industry, aluminum litho plate is mainly used for printed materials such as books, magazines, newspapers, etc. with a long printing cycle and requiring precise layout. In the packaging industry, aluminum plate for printing is mainly used for plate making of packaging boxes in the fields of food, daily chemicals, and medicines. In the field of advertising, it is mainly used for the production and printing of large billboards such as outdoor advertising and building advertising.

Aluminum printing plate Features

1. Corrosion resistance: Aluminum litho plate has good corrosion resistance and can remain stable in a variety of environments, thus ensuring the smooth progress of the printing process.

2. Lightweight: Compared with printing plates made of other materials, aluminum printing plates are lighter, easier to carry and operate, and are conducive to improving printing efficiency.

3. Good thermal conductivity: Aluminum alloy has excellent thermal conductivity, which enables the printing plate to quickly transfer heat during the printing process and ensure the printing quality.

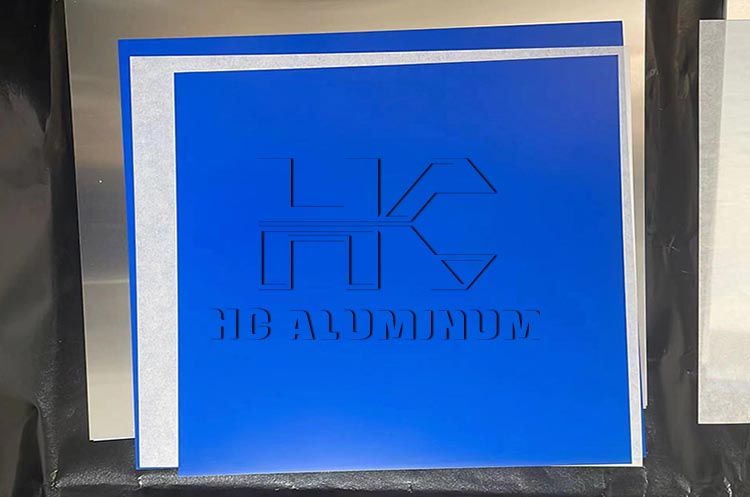

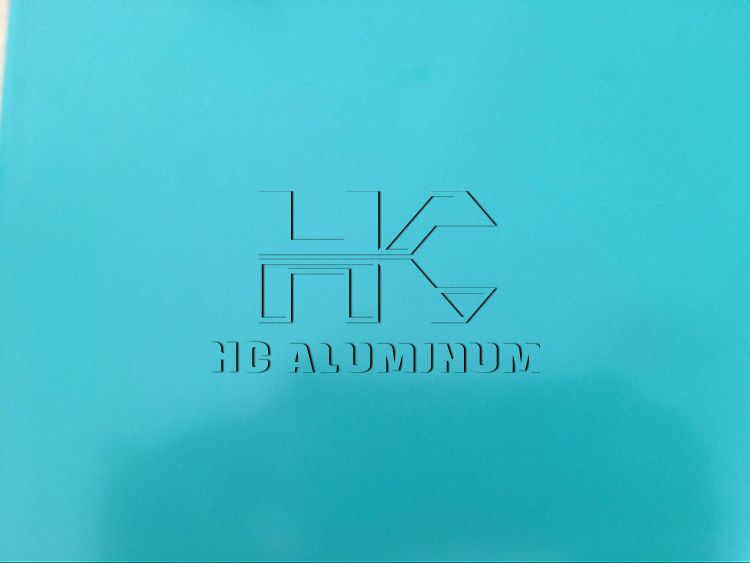

4. High precision: Aluminum plates for printing can transfer images and texts to printed materials with high precision, ensuring the exquisiteness and clarity of printed products.

5. Environmental protection: It can be recycled, will not pollute the environment, and will not produce harmful substances during the printing process.

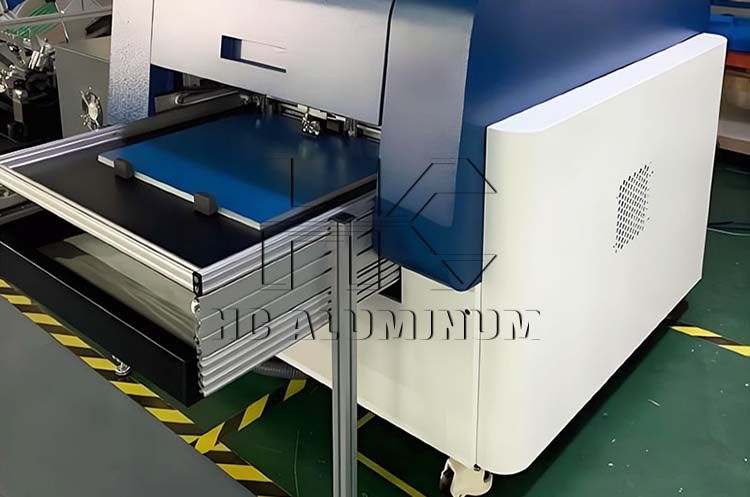

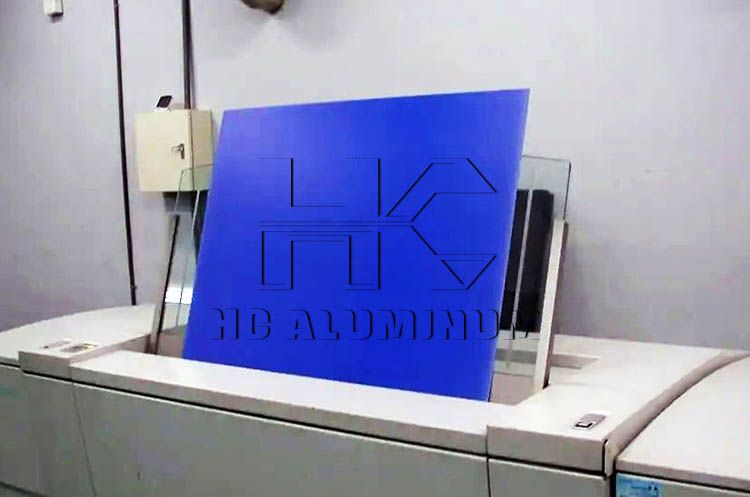

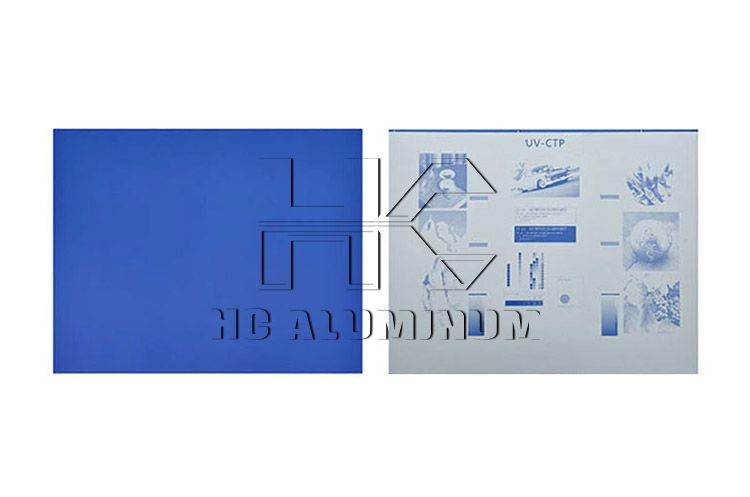

Generally, no matter it is PS plate or CTP plate, the developer is needed. CTP plate developer is mainly used in the printing industry to develop CTP plates. The main function of CTP developer is to help convert the latent image on the CTP plate into a visible image, thereby completing the platemaking process. Specifically, CTP developer develops the photosensitive material on the CTP plate through chemical reactions to form a clear image, which is crucial for the dot quality and printing effect during the printing process

There are two main types of CTP developers: ready-to-use and concentrated. Instant-use developers do not need to be mixed with water before use, and each batch undergoes strict quality control and inspection to ensure high-quality and stable output of dots. Its disadvantages are higher cost and larger volume.

Concentrated developer is cheaper and smaller in volume, but needs to be mixed with water before use, and its quality stability depends on the water quality. If the mixing ratio is incorrect or the water quality is poor, the development effect may be affected.