UV CTCP VS PS Printing Technology

UV CTP plate is a technology that inherits the advantages of CTP and can continue to use traditional offset printing plates. It realizes computer direct printing on traditional PS plates, so that plate issues are no longer an obstacle to digitalization, allowing printing companies to easily enter a "digital world".

Advantages of CTCP technologies

1. Low cost

The CTCP plate price is low. Although the price of CTP plates has fallen, it is still much higher than the cost of using ordinary PS plates. CTP plates are about twice that of CTCP plates. In addition, the equipment is simple to install. Its light source uses ultraviolet lamps, and its life has been increased to 2,500 hours. Its price is less than 1/10 of the laser light source, so the operation and maintenance cost of the equipment is very low.

2. Good compatibility with traditional processes

Since the CTCP system still uses the common PS plates that the printing factory is familiar with, the manufacturer can undoubtedly continue to use the various liquid chemicals, developing equipment and punching devices in the original plate-making process to achieve good compatibility between the plate-making system and the printing press.

For example, the original liquid ratio can be kept unchanged during the plate making stage; during the printing stage, the original printing pressure can be continued to be used because the properties of the plate remain unchanged. At the same time, the processes such as dampening and washing the plate on the printing press can remain unchanged. Therefore, printing companies do not need to worry about various problems caused by changes in printability, and do not need to spend a lot of time and energy to complete the matching of the printing plate and the printing press.

3. Excellent imaging quality

CTCP technology uses square pixel imaging, with clear and sharp dot edges. It can reproduce the gradation and level of FM dots with a diameter of 17 microns and images with a screen count of 200 l/in. It can also well complete the reproduction of images with a screen count of 250 l/in.

The German FORGRA Association has tested the dot reproduction of different types of CTP technology. The results show that the CTCP system and the thermal CTP system have the best dot reproduction. Moreover, with the development of DMD technology, the resolution of CTCP platemaking machines can be further improved, and the imaging quality will be better.

4. Reduce printing debugging time and material loss

As the printing industry has more and more short-run jobs, plate changing and machine debugging have become regular tasks. Reducing the time for printing debugging can significantly save time and cost. CTCP plate making is more accurate than traditional analog plate making, so the waste of consumables such as (wetting) water, paper, and ink is reduced during machine debugging.

5. Simple operation

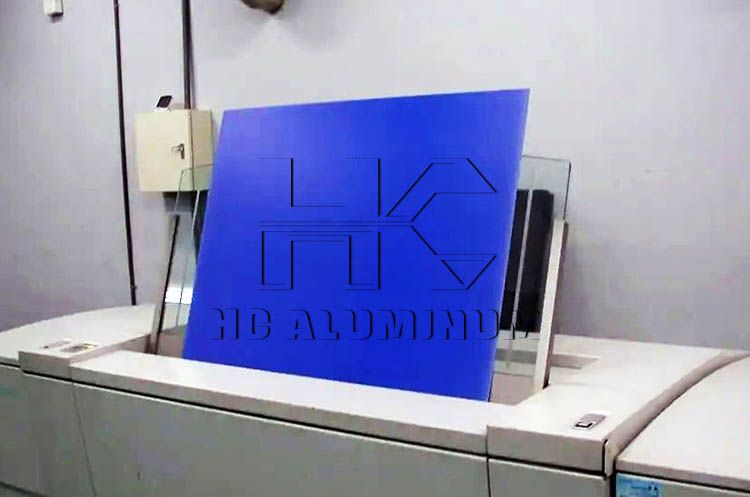

All UV materials (printing plates or proofing materials) can be operated in a bright room, and can easily develop printing plates of various sizes. It can also process multiple plates at the same time and can expose the same plate multiple times.

6. No need to change the current hardware configuration

CTCP plate can use 1-Bit/Tiff format data and RIP data, and can use conventional developers and processing chemicals, without the need for special network interfaces and process flows.

7. Wide supply of consumables

The quality and processing stability of traditional PS plates are well known, while CTP plates has higher price and high requirements for the working conditions. Welcome to inquire ctcp plate price from us.