Chinese Positive PS CTP Plate for Offset Printing Cut to Size

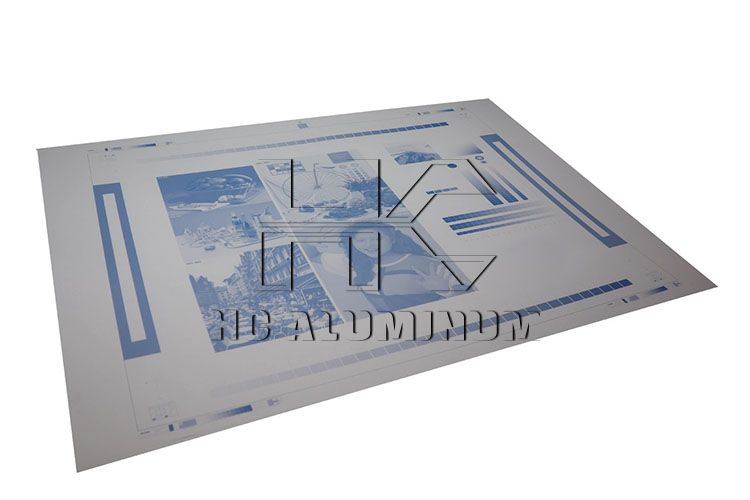

PS plate offset printing is the main printing plate for pre-printing at present. There are two types of PS plates: positive PS plates and negative PS plates. Among them, positive PS plates account for a larger share and are used in most medium and large printing tasks today. Its production process is also becoming more mature.

The main features of CTP plates are sensitivity. It has high sensitivity (13wJ/cm2) and resolution, wide spectral response, screen lines up to 300 lines/inch, good dot reproducibility, and dot coverage of 1%~99%.

Different types of CTP plates are suitable for different printing needs and CTP machines. CTP plates can be divided into the following categories:

Thermal CTP Plates: This type of CTP plate uses a heat-sensitive coating, and the laser head of the CTP machine applies heat energy to the surface of the aluminum plate to form an image. The coating on the non-exposed part is melted and removed by the heat energy to form a printed image.’

UV-CTP plates: It uses a UV-sensitive coating and forms an image through UV light exposure by the laser head of the CTP machine. The image is then cured by chemical treatment.

Processless CTP plates: This plate is usually a variant of thermal or UV CTP plates. They do not require wetting or chemical treatment to form an image, so they are called "waterless" printing plates.

Violet CTP plates: This plate uses hydrocarbons as the sensitive layer, and the laser head uses ultraviolet light to form an image. Violet CTP plates have advantages in cost, speed and image quality.

Although CTP computer to plate has been used for a long time and has begun to be popularized in many countries, some printing companies are still using PS plates. PS plates are still the most widely used printing plates worldwide.

In offset printing, plate making is the guarantee of printing quality. Only by ensuring the quality of PS plate making can the quality of printed products be ensured.

1. Original plate quality

The original plate refers to the film or sulfuric acid paper output by prepress. Its quality directly affects the PS plate making effect. There are two important indicators for the quality of the original plate:

(1) Dot density

When positive printing, the dots must have sufficient density, the density of a single dot is above 3.0, the solid density is above 3.5, and the transmission density of the blank area of the film should be less than 0.05.

(2) Smooth dots

The density of the center of the dots should be consistent with the density of the edges, so as to expand the tolerance of the exposure time. The original plate should be clean and free of dirt. It is best to use a complete film without a knife edge and collage tape to ensure that the film and the PS plate are tightly combined to avoid the dot blurring caused by light scattering.

2. Plate quality

(1) Plate base

The plate base should be clean, of uniform thickness, with uniform distribution of grains, moderate coarseness and depth. The photosensitive liquid should be evenly coated without bubbles or scratches. Generally, the average grain depth (RZ) is required to be between 5 and 7.5 μm, and the average roughness (Ra) is required to be around 0.6 μm.

(2) Photosensitive adhesive layer

The photosensitive coating should be uniform and of moderate thickness, which should completely cover the grain peaks, but not too thick to affect the resolution of the printing plate. Generally, the coating thickness of the PS plate is around 1.8 g/m2.