Several Common Printing Plate Materials and Their Characteristics

The printing plates are very important tools in the printing process, which determine the quality and effect of printing. Depending on different printing methods and printing needs, printing plates can use a variety of different materials. The following are several common printing plate materials and their characteristics:

1. Metal printing plates

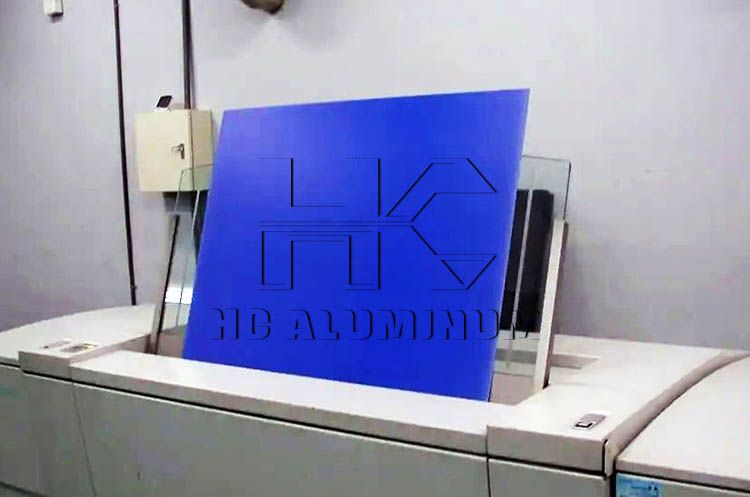

Aluminum printing plates: Aluminium plate lithography is one of the most common printing plates and is widely used in offset printing (lithography). Aluminum plates have excellent durability, good corrosion resistance and high-resolution image reproduction capabilities. Its surface is treated so that it can be combined with photosensitive materials to enable the image to appear on the plate. Aluminum plates have a long service life and are suitable for large-scale printing.

Zinc plates: Zinc plates were once used in lithography, but are now gradually replaced by aluminum plates. Zinc plates are relatively soft and easily worn, but their cost is relatively low and they are still used in some small-scale printing.

2. Polymer plates

Resin plates: Resin plates are mainly used for flexographic printing. Resin plates have good elasticity and adaptability and can be printed on uneven surfaces. Its surface can absorb ink well and is suitable for printing packaging materials such as plastic bags, cartons and paper cups. Resin plates also have high wear resistance and chemical resistance, which is suitable for long-term use.

Photopolymer plates: This type of plate is made by the exposure and development process of photosensitive materials and is widely used in flexographic printing and gravure printing. Photopolymer plates have high resolution, good durability and fine image reproduction capabilities. Its manufacturing process is environmentally friendly and it helps to reduce the use of chemicals.

3. Rubber Plates

Rubber plates are mainly used for relief printing, such as envelope, label and packaging printing. Rubber plates are soft and elastic, and can be printed on irregular surfaces. The plate-making process is relatively simple and low-cost, suitable for small-batch and multi-variety printing needs.

4. Ceramic plates

Ceramic plates are mainly used for special printing needs in high-temperature environments. Ceramic plates have extremely high wear resistance and heat resistance, and can maintain good performance in high-temperature environments. The production process is complex and the cost is high, but it has irreplaceable advantages in specific fields.

5. Digital printing plates

Digital printing plates emerged with the development of digital printing technology. It does not require the traditional plate-making process and directly controls the printing equipment through digital signals for printing. This printing plates for packaging are fast, efficient, and highly adaptable, and are suitable for small batches and multiple variations of printing needs.