What Are Aluminum Offset Printing Plates?

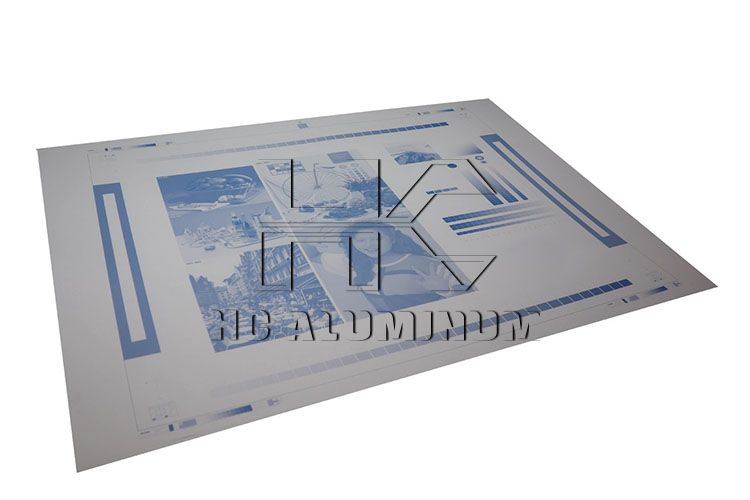

Offset printing is a traditional printing method and the method of lithography. It refers to the use of aluminium offset printing plates to transfer the graphic information you want to express and spread to the substrate, and finally make it into paper media such as books, newspapers, etc.

The aluminum alloy billet is rolled into a thin plate of a certain thickness through hot and cold rolling process. After the surface of the plate is treated by a specific process, a layer of photosensitive resin is coated, and after drying, it is made into a printing plate for various purposes.

PS plate is the main printing plate for pre-printing at present. Its plate-making process is simple and fast, and the plate-mounting operation is very convenient. It can print solids, lines, and has good printing reproduction effect. The printing price is relatively cheap, and it is widely used for printing packaging products such as facial tissue and paper boxes.

At present, thermal CTP plate technology and UV-CTP plate technology have become the mainstream technologies of offset printing plates worldwide. In the offset printing plate market, wash-free CTP plates do not require chemical reagents to be used for plate processing, avoiding the use of volatile and environmentally damaging chemicals, and are therefore more environmentally friendly.

What sizes are there for CTP printing plates? Generally speaking, CTP printing plates generally have various commonly used sizes from quarto to large full size, and the sizes of CTP printing plates can also be customized according to customer requirements. For example, CTP printing plates with a thickness of 0.3mm are: 1030*800, 1030*795, 1030*790, 1030*770, 920*760, 910*665, 790*595, 790*565, 766*605, 745*605, etc.

With the increasing maturity and rapid development of CTP technology, as well as the continuous decline in the CTP plate price, CTP technology has become more and more popular among printing practitioners, and the use of CTP plates is also rapidly catching up with the traditional PS plates.

CTCP technology inherits the dvantages of CTP and can continue to use traditional offset printing plates. It has become another highly competitive direct platemaking technology after thermal CTP and ultraviolet laser CTP.

CTCP printing uses short-arc ultraviolet high-pressure mercury lamp as the exposure light source. Compared with CTP equipment that uses laser as the light source, the maintenance of CTcP exposure head is more convenient and easier; the replacement of light source does not require professionals, and ordinary operators can complete it.

Several Common Printing Plate Materials and Their Characteristics