What Is The Printing Plate Market

The global offset printing plate market size was estimated at USD 9.13 billion in 2024 and is expected to reach USD 12.5 billion by 2032, at a CAGR of approximately 4.01% during the forecast period. Offset plates are used in various applications such as commercial printing, newspaper printing, packaging, etc.

The growth of the market is due to the increase in packaging demand and the growth of the printing industry. The demand for this product is growing as it provides excellent print quality and is cost-effective, making it an attractive printing option. In addition, the substantial growth in the packaging industry has also driven the demand. These printing plates are widely used in the packaging industry due to their ability to print on a variety of substrates, which is essential for printing on packaging materials.

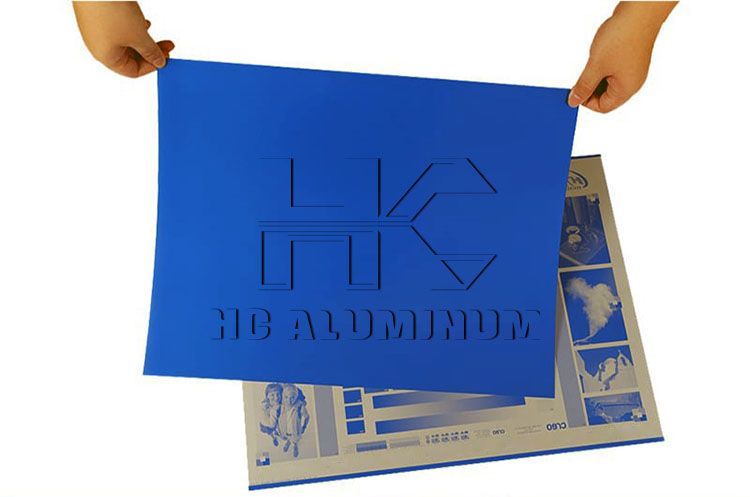

Offset printing plates are photosensitive plates used in offset printing and are important consumables that are indispensable for offset printing. Offset printing plates have the advantages of rich variety, clear printing, and stable quality. They are widely used in the publishing, packaging, and advertising industries.

With the continuous development of the printing industry and the dominant position of offset printing technology in my country's printing industry, the production and sales scale of offset printing plates in China has continued to expand, and the production capacity has been in a leading position in the world.

There are many types of offset printing plates. According to the different optical properties of the photosensitive layer, offset printing plates can be divided into negative plates and positive plates; according to the different photosensitive wavelength ranges, they can be divided into positive CTCP plate and thermal CTP plate.

UV-CTP plates(CTCP) and thermal CTP plates are representative products of offset printing plates and are widely used in the field of commercial printing. The photosensitive wavelength range of UV-CTP plates is 405-410nm, which has the advantages of fast plate making and large processing tolerance; the highest photosensitive wavelength of thermal CTP plates in the infrared region reaches 830nm, which has the advantages of high printing adaptability and good dot reproducibility.

The main raw materials of offset printing plates include aluminum coils, photosensitive materials, backing paper, etc. Aluminum coils are the core raw materials of offset printing plates, which can manufacture substrates and account for nearly 80% of their production costs. Haomei Aluminum provide such raw materials.

The digital image is transferred to a printing plate and then printed onto a surface in the offset printing process. Digital offset printing plates are specialty plates used in this process. The process combines the advantages of contemporary digital breakthroughs with those of traditional offset printing, offering a high degree of consistency and precision.

The demand for digital offset printing plates is increasing due to the widespread adoption of digital printing in areas such as publishing, advertising, and packaging. These plates are essential for contemporary printing services as they help maintain the clarity, vibrancy, and durability of print quality.