What Will CTP Violet Plates Bring for You

CTP violet plates are usually composed of multiple functional layers, each of which works together to achieve high-quality platemaking effects. Generally speaking, its basic structure includes a base, a photosensitive layer, and a protective layer.

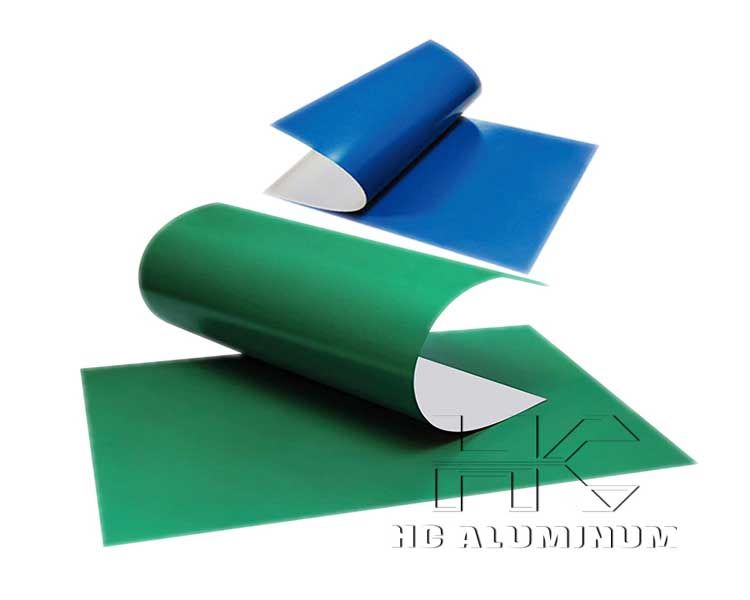

Base: The base is mostly made of specially treated aluminum plates with good flatness, strength, and conductivity. The surface of the aluminum plate is electrochemically roughened and anodized to form a uniform aluminum oxide layer, which not only increases the adhesion between the base and the photosensitive layer, but also improves the printing resistance of the plate.

Photosensitive layer: The photosensitive layer is the core part of the plate. It is sensitive to violet laser and can undergo photochemical reactions under laser irradiation. The photosensitive layer of violet laser CTP plate is mainly composed of photopolymer materials. When the violet laser with a wavelength of about 405nm irradiates the photosensitive layer, the photosensitive material in the exposed area will undergo polymerization reaction to form a graphic part with a certain hardness and printing resistance; while the photosensitive material in the unexposed area will be removed in the subsequent development process.

Photosensitive layer: The photosensitive layer is the core part of the plate. It is sensitive to violet laser and can undergo photochemical reactions under laser irradiation. The photosensitive layer of violet laser CTP plate is mainly composed of photopolymer materials. When the violet laser with a wavelength of about 405nm irradiates the photosensitive layer, the photosensitive material in the exposed area will undergo polymerization reaction to form a graphic part with a certain hardness and printing resistance; while the photosensitive material in the unexposed area will be removed in the subsequent development process.

Features

High resolution: The wavelength of violet laser is relatively short, generally between 405nm and 410nm, which allows its laser spot to be controlled very small, reaching 1μm or even smaller. Combined with high-precision platemaking equipment and photopolymerized violet laser CTP plates, users can easily achieve the platemaking accuracy requirements of 300-line AM screening and 20μm FM screening, meeting the printing companies' demand for high-quality platemaking. Whether it is fine image details or tiny text lines, violet laser CTP plates can be clearly reproduced, laying the foundation for high-quality printing.

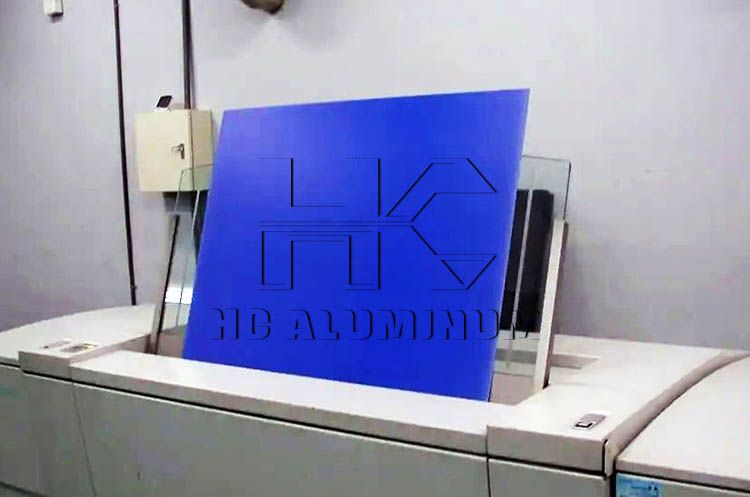

High platemaking efficiency: From the physical properties of light, the shorter the characteristic spectrum, the greater the energy. Compared with other commonly used CTP light sources, such as green light (532nm) and red light (830, 1064nm), violet light sources have higher imaging speeds. The small size and high degree of modularity of violet laser diodes allow platemaking equipment to be designed more compactly and achieve high-speed scanning.

Some advanced violet laser CTP platemaking machines can greatly increase the platemaking speed while ensuring the quality of platemaking, greatly shorten the platemaking time before printing, and improve production efficiency. They are especially suitable for commercial printing and newspaper printing with high time requirements.

Good stability: violet laser is a cold light source, and its stability is better than some other light sources. In the platemaking process, a stable light source can ensure the consistency of exposure and reduce the platemaking quality problems caused by light source fluctuations.

The violet laser CTP equipment adopts a mature and stable internal drum mechanical structure. The stability and reliability of this structure have been verified in the long-term production and application practice of traditional platemaking equipment typesetting machines.

The internal drum structure avoids the problems of plate jamming, flying plates and uneven flat screen caused by spiral imaging that often occur in external drum thermal CTP, and further ensures the accuracy and stability of platemaking imaging.

Environmental advantages: With the increasing requirements for environmental protection, the printing industry is also constantly seeking more environmentally friendly solutions. Violet laser CTP plates have certain advantages in this regard. Some violet laser photopolymer plates have a large developer tolerance and a long service life, which reduces the frequency of developer replacement and the amount of waste liquid generated.

The emergence of violet laser chemical-free washing plates has provided strong support for the realization of green printing. The amount of printing plate glue used in this plate is very low, and the waste liquid generated is very small. The waste liquid generated is less than 1/20 of traditional film platemaking and 1/10 of traditional direct platemaking plates. It also saves the cost of developer and reduces pollution to the environment.

Cost-effectiveness: violet laser CTP plates have certain advantages in terms of cost. On the one hand, due to its high platemaking efficiency, more platemaking tasks can be completed in a shorter time, thereby improving the utilization rate of equipment and reducing the unit platemaking cost. On the other hand, the manufacturing cost of violet laser CTP platemaking machines is relatively low.

The wavelength of violet laser is short, which makes it easy to achieve long-distance transmission of light, so that cheap semiconductor lasers can be used in internal drum CTP direct platemaking machines, reducing the purchase cost of equipment.

Moreover, the service life of violet laser diodes is relatively long. Many platemaking machine manufacturers believe that its service life is longer than 10 years, which also reduces the cost of equipment maintenance and replacement. Welcome to inquire CTP costs from us.

Which Printing Plates Choose Aluminum Plates As Raw Materials