What Are Requirements of Printing Presses on Metal Printing Plates

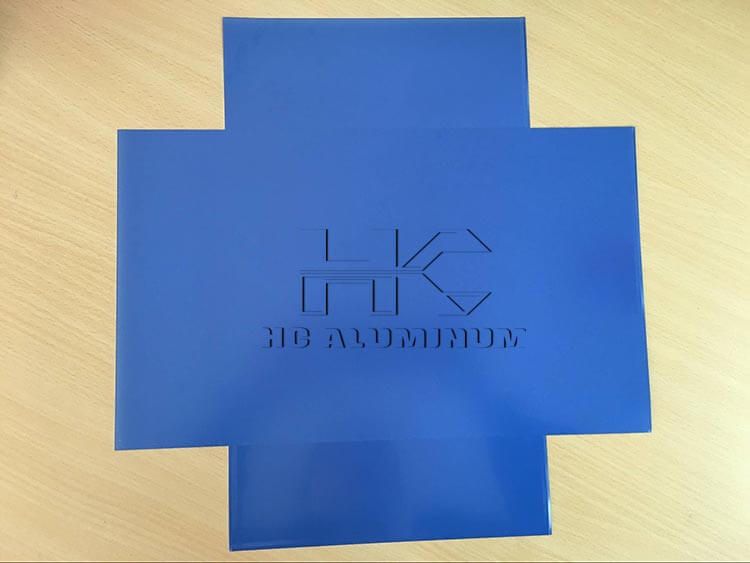

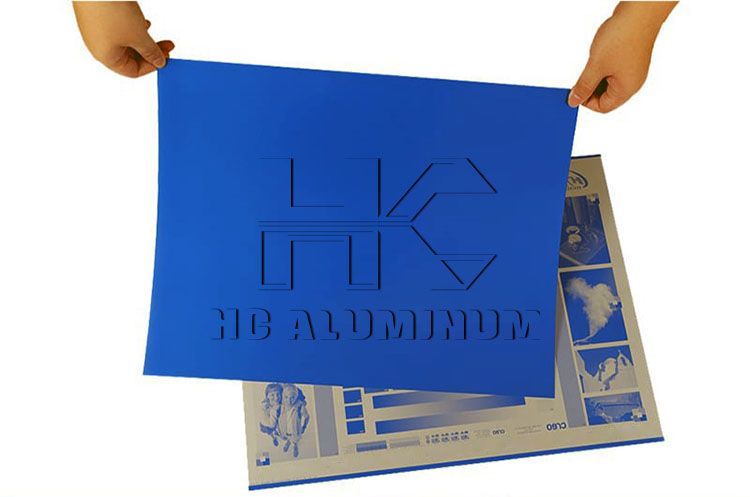

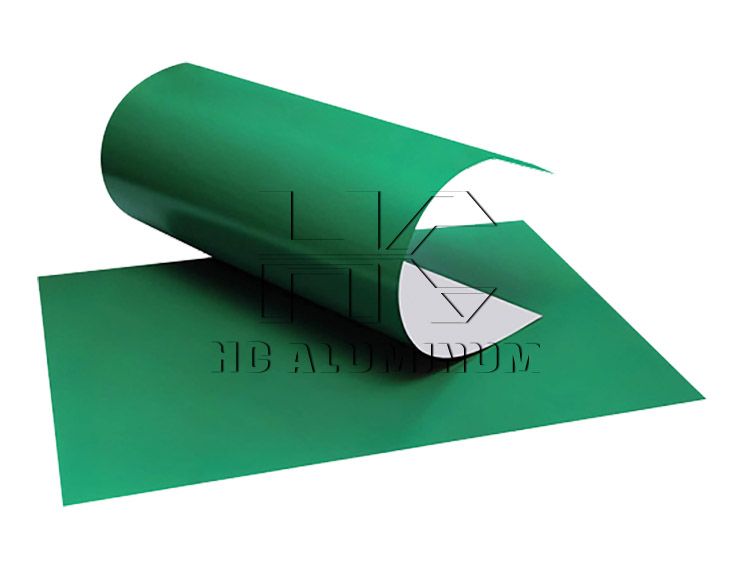

The performance of metal printing plates for sale is determined by the material properties, and the appropriate metal type needs to be selected according to the printing requirements. Aluminum printing plates are known for their light weight (density 2.7g/cm³) and corrosion resistance, and are suitable for offset printing, such as pattern printing on food packaging.

Copper printing plates have excellent thermal conductivity (386W/m・K), which makes them outstanding in electronic circuit printing and can achieve fine line engraving below 0.1mm. Stainless steel plates (HRC 20-30) are known for their high hardness (HV 200-300) and wear resistance, and are often used for embossing of industrial machinery nameplates.

Zinc plate (HBS 80-100) has become the mainstream choice for flexographic printing due to its easy processing and cost advantages. It can achieve a 0.3mm depth of graphic structure through chemical etching process.

Technical adaptation requirements of printing press

1. Offset Press

Surface treatment: The metal plate needs to be anodized to form a 3-5μm oxide film to improve hydrophilicity (contact angle < 15°) and ink adsorption.

Thickness tolerance: The standard thickness is 0.15-0.3mm, and the tolerance is controlled within ±0.005mm to ensure overprint accuracy.

Ink compatibility: Use UV offset ink with high viscosity (200-300Pa・s), and the curing speed must match the printing speed (8000-15000 sheets/hour).

2. Gravure Press

Cell depth: The cell depth of the electronic engraved gravure needs to be adjusted according to the ink characteristics, such as 80-120μm for solvent-based inks and 100-150μm for water-based inks.

Surface hardness: The thickness of the chrome plating layer is 0.02-0.03mm, and the hardness is above HV 800 to resist the pressure of the scraper (20-50N/cm).

Tension control: The printing tension needs to be stable at 5-15N to avoid pattern distortion caused by deformation of the metal plate.

3. Flexo Press

Plate hardness: The hardness of the photosensitive resin plate is Shore A 30-40, and the metal base needs to provide a support thickness of 1.7-2.2mm.

Dot expansion: The dot expansion rate is controlled within 15% through laser engraving technology to ensure color reproduction.

Ink transfer: Use low viscosity (20-50mPa・s) water-based ink, combined with ceramic anilox roller (line count 800-1200lpi) to achieve precise ink supply.

By scientifically selecting metal materials, accurately adapting the technical parameters of printing presses, and combining advanced platemaking processes and maintenance strategies, printing press plates for sale are developing in the direction of high precision, high efficiency, and greenness.