What Is Developing Trend of Newspaper Printing

The printing industry is an important part of the national economy and one of the fastest-growing industries in the past decade. The basic requirement of newspaper publishing is always to make news appear in the newspaper in the shortest time with good printing quality.

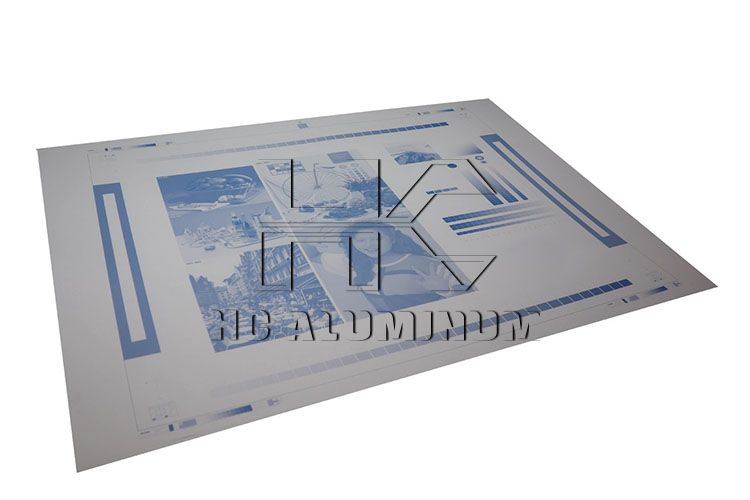

In each link of newspaper publishing, improving the speed of each link, such as text entry, typesetting, image scanning, plate making, printing, etc., is the main way to shorten the time. Cutting off one link will be more effective. Direct plate making can shorten the process and improve plate making efficiency.

Using direct platemaking technology to produce a black and white PS plate, the first one takes about 3 minutes, and the continuous ones take about 1 minute; the first one of the color plates takes about 5 minutes, and the continuous ones take about 2 to 2.5 minutes.

The most important thing is that the registration of 4 different color plates is automatically controlled by a computer, without manual errors, and its repetition accuracy can reach ±0.005 mm. Therefore, the platemaking process moving towards CTP plate is an improvement, and it has pushed the digital flow of the entire publishing process forward one step.

Strengthening and improving printing capacity is an urgent task at present. It is expected that the types of newspapers will not increase in the future, and may even decrease, but the expansion of newspapers is an inevitable trend.

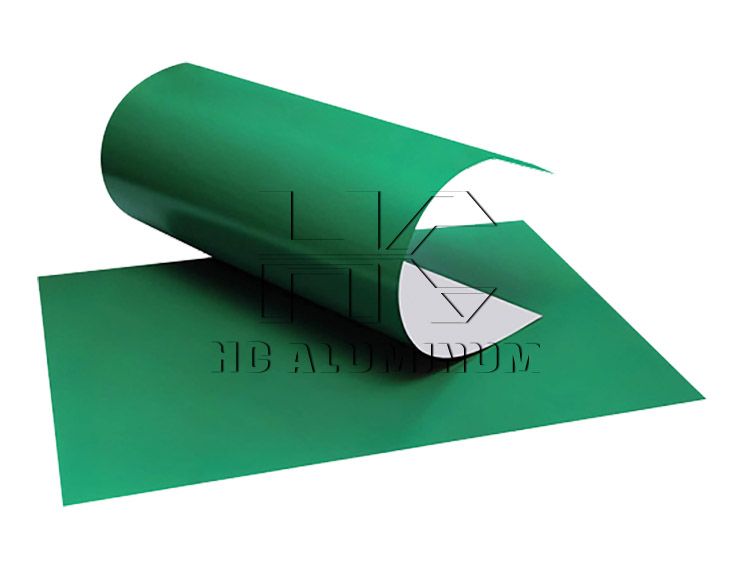

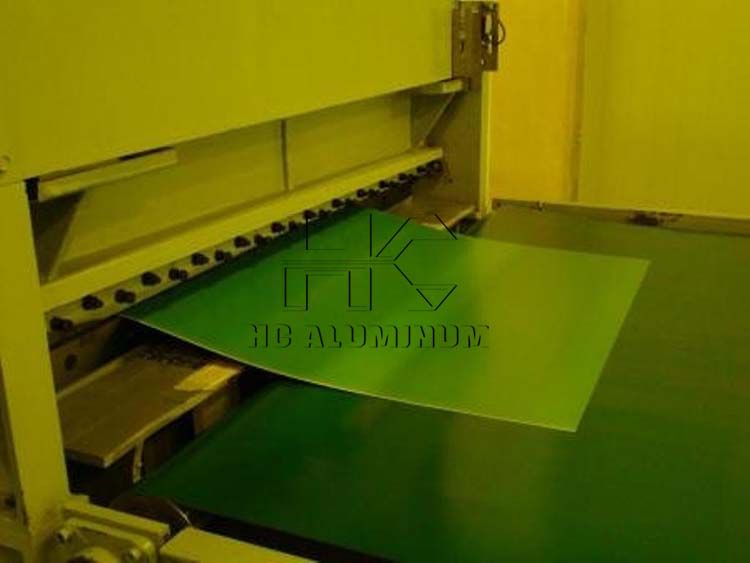

At present, there are two main categories of aluminum newspaper printing plates in the market: thermal CTP and violet CTP plate. Thermal CTP uses an external drum laser scanning method to make plates. The plate is fixed outside the drum and rotates at high speed with the drum during plate making. The violet CTP mostly uses an internal drum laser scanning method to make plates. The plate is placed inside the drum. During plate making, the plate remains stationary and the laser head scans at high speed.

The waterless CTP printing plate is coated with a photosensitive layer and a silica gel layer on an aluminum plate base, and the silica gel is used to repel ink. The waterless plate is exposed through a heat-sensitive CTP plate machine, and a near-infrared (near 830nm) laser is used to form a pattern on the plate.

Compared with traditional water-based printing, printing proof paper can be reduced by about 30%, printing efficiency is increased by 20%, and VOC (volatile organic compounds) and CO2 emissions produced by fountain solution are reduced by 90%. In terms of environmental protection, the effect is remarkable. Welcome to leave message below to inquire CTP price.