Offset Printing: One Popular Type of Lithography

Five essential elements of printing technology

1. Original: In the field of printing, the graphic information on the physical object or carrier based on which the plate is made is called the original. Printing originals can be divided into text originals and image originals (including painting originals, prints, photos, reversal films, but not negatives).

2. Printing plate: The printing plate is a printing carrier used to transfer ink to the substrate. The graphic information on the original is made on the printing plate, and there are graphic parts and non-graphic parts on the printing plate. The graphic part on the printing plate is the inked part, so it is also called the printing part. The non-graphic part does not absorb ink during the printing process, so it is also called the blank part.

3. Substrate: Various materials that accept printing ink or absorb colorants and present images.

4. Printing ink: It is an imaging material that is transferred to the substrate during the printing process. The substrate transfers the image from the printing plate. The display of the image is formed by the colorant and can be fixed on the surface of the substrate to form a printed ink mark.

5. Printing machinery: It is a general term for machines and equipment used to produce printed products. Printing machines can be divided into letterpress printing machines, offset printing machines, gravure printing machines, stencil printing machines, special printing machines, etc. according to the type of printing plate.

Lithography

Offset printing is a type of lithographic printing. Due to its advantages such as fast printing speed, relatively stable printing quality, and short printing cycle, books, newspapers, and a considerable part of commercial printing are all using offset printing. The lithography aluminum plate is used for this printing.

Three principles of offset printing

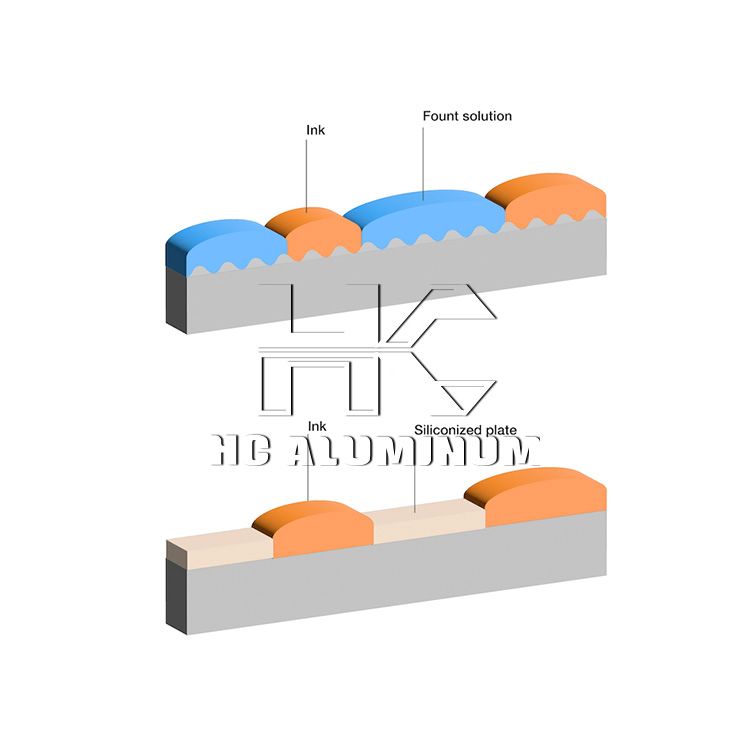

1. Water and oil are incompatible: The slightly polar water molecule structure is different from the non-polar oil molecule in terms of molecular polarity, which results in the inability of water and oil to attract and dissolve each other. The existence of this rule makes it possible to use water on a flat printing plate to distinguish between images and blank parts.

2. Surface adsorption: Depending on the surface tension, it can adsorb different substances, which also makes it possible to separate images and texts in offset lithography.

3. Dot composition: Since the offset printing plate is flat, it is impossible to rely on the thickness of the ink to show the layers of the images and texts on the printed matter, but by splitting the different layers into very small dot units that are imperceptible to the naked eye, it is possible to effectively show the rich image layers.

Offset aluminum plates can be roughly divided into PS plates, CTP plates, etc. Among them, PS plates can be subdivided into positive PS plates and negative PS plates; CTP plates can be subdivided into thermal CTP plates and UV-CTP plates. Since CTP plates have a relatively simple plate-making process and a high degree of restoration of printed products, CTP plates have gradually become the mainstream product of offset printing plates.