What Are Advantages of Aluminum Offset Printing Plates

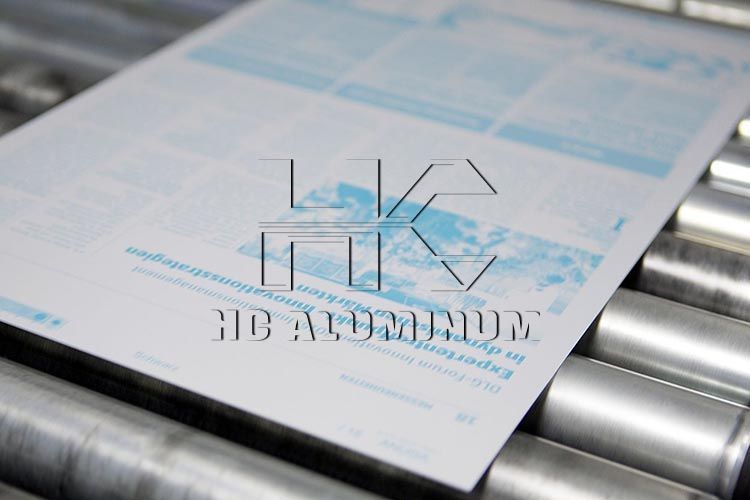

The technological development in the field of printing plates has also promoted the progress of offset printing technology time and time again. Whether it is the laser typesetting technology that completely ushered in light and electricity for printing, or the substantial improvement in production efficiency from the PS plate era to the CTP plate era, plate technology has become the internal driving force of printing.

The surface of the aluminum alloy plate is electrolytically ground, anodized and coated with a layer of photosensitive material for printing. It is used to produce PS Plate, UV CTP plate, thermal CTP Plate, Violet CTP plate, processless CTP plate,etc.

Aluminum printing plates have excellent durability, good corrosion resistance and high-resolution image reproduction capabilities. Its surface is treated so that it can be combined with photosensitive materials to enable the image to appear on the plate. Aluminum plates have a long service life and are suitable for mass printing.

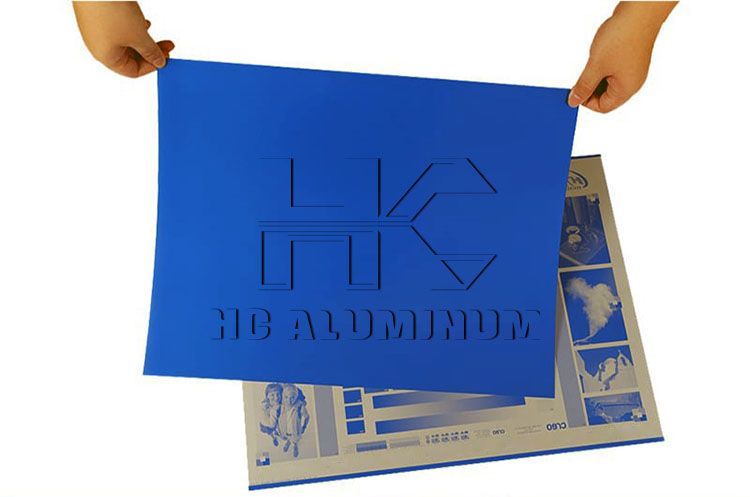

PS plate for offset printing has two types: positive PS plates and negative PS plates. Among them, positive PS plates account for a larger share and are used in most medium and large printing tasks today. Its production process is also becoming more mature. The photosensitizer commonly used for positive PS plates is a soluble diazohydroquinone-type photosensitive resin, and the photosensitizer commonly used for negative PS plates is an insoluble azido-based photosensitive resin.

Thermal CTP plates are the most widely used CTP plates at present. It uses thermal imaging technology to make plates and is very sensitive to the heat energy of lasers, so it can achieve high-precision image and text transfer. Thermal CTP plates are suitable for high-quality commercial printing and publication printing, such as high-end magazines, albums, brochures, etc. Since thermal plates have good adaptability to ambient temperature and humidity and do not require preheating, they are widely favored by printing companies.

The so-called violet light source is a laser with a wavelength of 400nm, and the shorter the wavelength, the greater the energy. Therefore, the violet light source can have a higher imaging speed than other commonly used CTP light sources such as green light (532nm) and red light (830 or 1064nm).

Since the violet plates for ctp is ineffective against red light and green light, the violet CTP plate can use a yellow full light (light + green light = yellow light), providing operators with a brighter working environment and making operation more convenient.

What Are The Benefits of Positive PS Plate for Offset Printing