What Are Different Types of Offset Printing Plates

At present, offset printing plates are mainly divided into two types, namely PS plate and CTP plate. As a mainstream plate making technology, CTP plate has many types: thermal CTP plate, UV-CTP plate, violet CTP, process free CTP plate,etc.

Violet plates for CTP is a high-speed millisecond instantaneous exposure at a certain wavelength (mostly 405nm now), so the requirements for UV-CTP plates are much higher accordingly. Now UV-CTP technology has been promoted in the printing design platemaking industry in China and even around the world, and its application value is immeasurable. UV-CTP plates are divided into negative and positive types.

Thermal CTP plates are currently the most widely used CTP plates. It uses thermal imaging technology to make plates and is very sensitive to the heat energy of the laser, so it can achieve high-precision image and text transfer.

Thermal CTP plates are suitable for high-quality commercial printing and publication printing, such as high-end magazines, albums, brochures, etc. Because thermal plates have good adaptability to ambient temperature and humidity and do not require preheating, they are widely favored by printing companies.

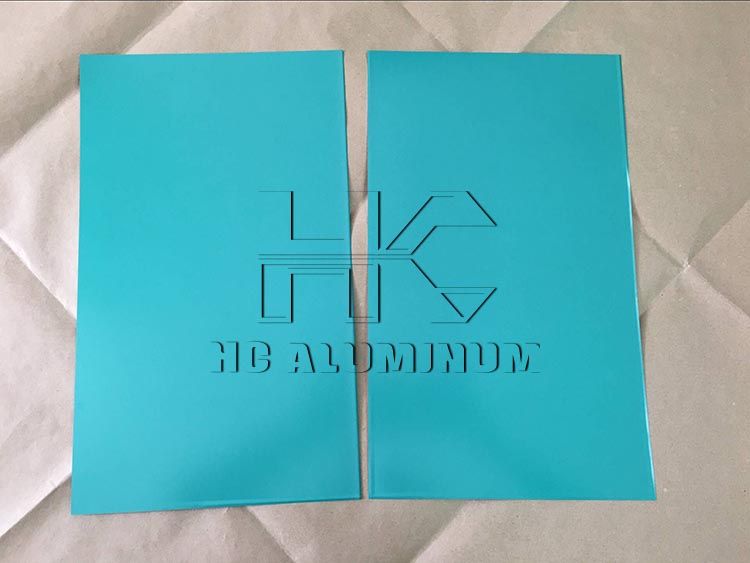

Thermal double-layer CTP plate is an offset printing plate used in the printing industry, mainly used in digital platemaking (CTP, Computer-to-Plate) technology. It has two main layers: a heat-sensitive layer and a base layer.

Single-layer thermal CTP plates are mainstream products in the printing industry, with a high market share. However, single-layer thermal CTP plates cannot meet the requirements of long printing runs and UV-resistant ink printing.

The double-layer thermal CTP plate not only retains the excellent printing performance of the traditional single-layer thermal CTP plate, but also can meet the printing requirements of long printing runs and UV-resistant inks.

The waterless CTP printing plate is a photosensitive layer and a silicone layer coated on an aluminum base. The silicone is used to repel ink. The waterless offset plates is exposed by a thermal CTP plate-making machine, and a near-infrared laser (near 830nm) is used to form a pattern on the plate.

Compared with traditional water-based printing, the printing proof paper can be reduced by about 30%, the printing efficiency can be increased by 20%, and the VOC (volatile organic compounds) and CO2 emissions generated by the fountain solution can be reduced by 90%, which is very beneficial to environmental protection.