What Is The Trend of The Offset Printing CTP Plate

As a key part of digital printing pretreatment technology, CTP plates' market size is affected by the digital printing market. Digital printing technology has experienced significant growth over the past few years as it gradually replaces traditional printing methods due to its high efficiency, low cost and personalized printing capabilities. The expansion of the global digital printing market directly promotes the growth of the offset printing CTP plate market.

CTP is an efficient and environmentally friendly digital prepress platemaking technology. CTP plates can be divided into the following categories: thermal CTP plates, UV CTP plates, waterless CTP plates, and violet CTP plates.

Thermal CTP plate is the most widely used CTP plate at present. It is made by thermal imaging technology and is very sensitive to the heat energy of the laser, so it can achieve high-precision image and text transfer. Thermal CTP plate is suitable for high-quality commercial printing and publication printing, such as high-end magazines, albums, brochures, etc.

UV CTP technology uses high-sensitivity UV CTP plate specially produced for it. The grain of this plate is finer than that of traditional plates, and the coating process is more complex. Of course, the photosensitive layer is also different from traditional PS plates. After development in recent years, violet CTP plate has become the three mainstream CTP technologies together with thermal CTP and CTCP.

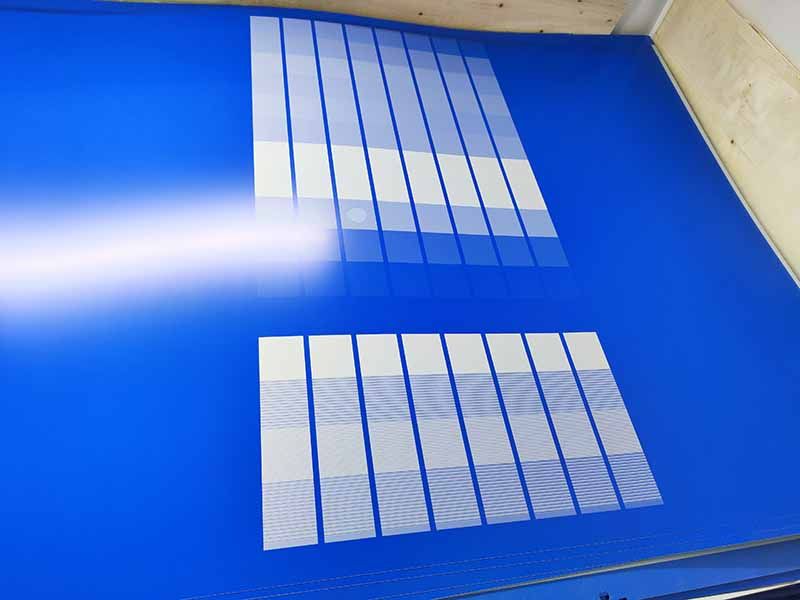

The processless plates are coated with a photosensitive layer and a silica gel layer on an aluminum plate base, and the silica gel is used to repel ink. The processless aluminum plates are exposed through a heat-sensitive CTP plate machine, and a near-infrared (near 830nm) laser is used to form a pattern on the plate.

After development by a plate processor, the silicone part irradiated by the laser will fall off, leaving the non-image and text (blank) part of the silicone; through dyeing, a stable image and text part will be formed, which is a negative pattern plate.

Compared with traditional water-based printing, printing proof paper can be reduced by about 30%, printing efficiency is increased by 20%, and VOC (volatile organic compounds) and CO2 emissions produced by fountain solution are reduced by 90%.