What Are The Printing Plates for Packaging

The offset printing plates are used in various applications such as commercial printing, newspaper printing, and packaging. The growth of the market is due to the increase in packaging demand and the growth of the printing industry. Offset printing plates are photosensitive plates used in offset printing and are important consumables that are indispensable for offset printing.

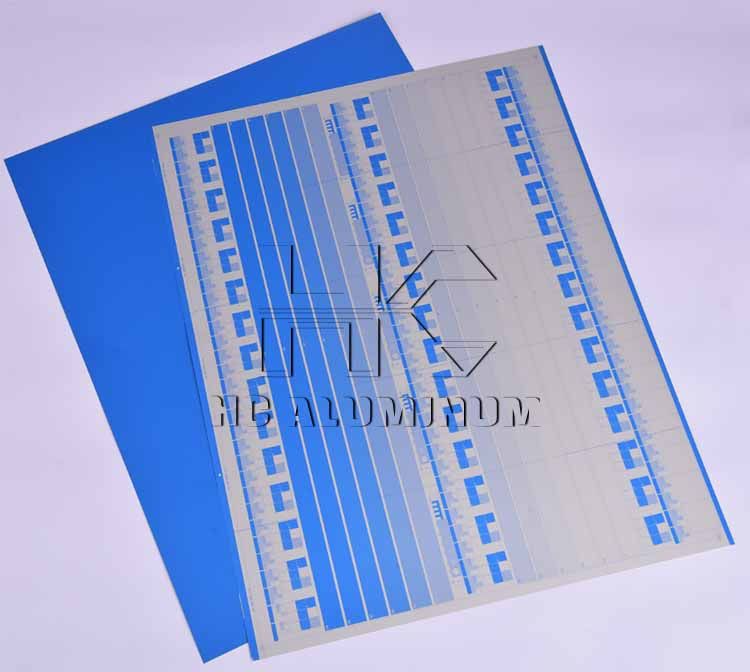

At present, there are two main types of printing plates for packaging, namely PS plates and CTP plates. PS plates are currently the main printing plates for pre-printed cartons. Because of its simple and fast platemaking process, the plate installation operation is very convenient. The printing reproduction effect is good, the printing price is relatively cheap, and it is widely used in printing packaging products such as carton paper and paper boxes.

There are two types of PS plates: positive PS plates and negative PS plates. Among them, positive PS plates account for a larger share and are used in most medium and large printing tasks today. Its production process is also becoming more mature. The commonly used photosensitizer for positive PS plates is soluble diazohydroquinone-type photosensitive resin.

CTP plate can be further divided into thermal CTP plates, UV-CTP plates and other kinds. Thermal CTP plates are currently the most widely used CTP plates. Thermal plates for printing are suitable for high-quality commercial printing and publication printing, such as high-end magazines, albums, brochures, etc.

Violet CTP plates belong to the visible light series. Since red light and green light do not work for violet CTP plate, its CTP equipment can use yellow safety lights (light + green light = yellow light) to provide operators with a brighter working environment and make operation more convenient.

Thermal double-layer CTP plate has two main layers: thermal layer and base layer. The advantages of thermal double-layer CTP plate include improved printing quality, reduced production time, reduced chemical usage, and improved production efficiency. It is widely used in commercial printing, packaging printing and other fields. Haomei Aluminum has all the mentioned aluminum plates. Welcome to inquire what you need from us.